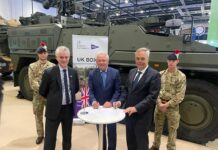

The Boxer is characterized by its modular design. It consists of two key elements: the driving module and the removable mission module. FFG Flensburger Fahrzeugbau Gesellschaft mbH (FFG) will present a recovery module for the Boxer to a specialist audience for the first time at the DSEi in London in September.

Depending on the national usage concept, different mission modules have now been developed for the Boxer, which is used internationally in different versions. As of today, mission modules are available for the following capabilities:

- Ambulance,

- Battle damage repair,

- Cargo,

- Command post,

- Engineer group,

- Armoured wheeled,

- Armoured personnel carrier,

- Self-propelled howitzer,

- Driving training vehicle and

- Infantry Fighting Vehicle.

In addition, further modules (e.g. mortar carriers) were designed at least on the drawing board. A module for use of the Boxer as a recovery vehicle, as now presented by FFG, has not yet been realized. The need for such a module results from operational concepts of armed forces, which require as homogeneous an equipment as possible. The British armed forces, for example, are calling for a mechanised – self deployable – brigade sized element with the following capabilities in the so-called “strike” concept:

- Independent and rapid deployment capability over a distance of up to 2,000 km to NATO borders.

- Ability to defeat light forces on arrival in theater.

- Capability to sustain combat effectiveness against irregular forces.

- Have sufficient organic recce and surveillance capacity to ensure permanent surveillance of a broad front.

- Have adequate SHORAD assets to protect itself against manned and unmanned aerial attacks.

For these requirements to be successfully met by combat units, the supporting elements (for example logistic- and fire-support) must also meet the same requirements, including mobility and protection.

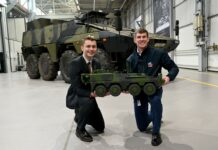

FFG has given ESD a preview of the recovery module, which should be able to meet such requirements and will be presented below.

FFG´s Boxer Recovery Module

The company said that development of the recovery module started in October 2017. In March 2019 the assembly of the first module began in Flensburg, operational functional tests of the module followed in July 2019. Extensive system tests are to be carried out after the presentation at DSEi. After that the concept of the recovery module is to be prepared for serial production.

The module is armoured, weighs approx. 13 tons and can be equipped with a remote-controlled weapon station from various manufacturers, including the FLW 200, depending on customer requirements. It offers space for two crew members, commander and gunner. The driver’s seat remains in the driving module with direct access to the recovery module. In order to ensure maximum logistical commonality with the other mission modules, already existing components (e.g. CBRN protection, Heating, Ventilation and Air Conditioning systems) are used wherever possible in the recovery module.

The recovery module is connected to the drive module only via standard Boxer mechanical interfaces and requires a power connection for operation in order to charge the integrated battery of the module. The hydraulic system is driven by the battery, which means that the recovery module can also be used independently of the drive module.

Technical Data

- Length of the pivoting crane boom 5.3 m

- Lifting force of crane boom 20 t

- Tensile force of the capstan winch 20 t

- Length of the capstan winch (Kevlar rope) 60 m

Concept

According to FFG, the pivoting crane boom is capable of carrying out all standard repair and recovery missions. This includes, for example, changing engines (including its own), weapon towers or lifting the boxer for a wheel change. In addition, the module is equipped with a capstan winch at the rear, which can also be used for self-recovery, and has a wide range of special tools (cutting and welding equipment, pneumatic power tools).

The module is stabilized by two hydraulically extendable support legs on the side in connection with a “rear anchor.” They secure the Boxer during crane and winch operations and simultaneously relieve the driving module of the associated stress.

The semi-autonomous electro-hydraulic design of the module allows it to be used even when the engine is switched off. All systems are controlled and monitored centrally via touchscreen displays and FFG’s own software. In emergency mode, the hydraulics can be operated via a manual control system.