With the order for more than 500 Boxers from the British Ministry of Defence the Armoured Transport Vehicle (GTK) Boxer is on its way becoming one of the most successful vehicles in the 8×8 (Boxer) class in the last 20 years.

At the International Armoured Vehicles Conference (IAV) in London, representatives of the European procurement authority OCCAR EA and the manufacturer ARTEC presented the current status and prospects of the project. The NSPA explained how the Boxer User Group supports the operation of the vehicles.

Production

The Boxer is manufactured by ARTEC, a joint venture of Rheinmetall and Krauss-Maffei Wegmann, which recently delivered the 539th vehicle for the three countries that have so far used it: Germany, the Netherlands and Lithuania. Production of the 91 vehicles for Lithuania will be completed at the turn of 2020/2021. Of the 2nd lot of Boxer (131 vehicles) for the Bundeswehr, around 60 have been handed over to the users. The last vehicle of the 2nd lot is expected to be delivered in mid 2021.

On the production lines, the Australian order under the aegis of Rheinmetall is taking up more and more space. Following delivery of the first Boxer in September 2019, a total of 25 will be manufactured entirely in Germany and transported to Australia as a kit for final assembly. From 2021, a substantial proportion of the Boxers will be produced by partner companies in Australia.

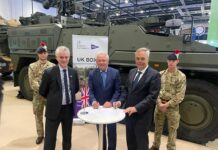

The industry to be involved is currently being selected for the UK boxers. The first contract has recently been signed with WFEL. Soon, production of the five prototyp vehicles will start in Germany. From mid 2022 on, the future user will test them and release them for serial production. About 60 percent of the production will take place at the Telford (Rheinmetall BAE Systems Land) and Stockport (KMW subsidiary WFEL) sites. The first production vehicle is scheduled to be handed over at the beginning of 2023. The 528 Boxers ordered are to be delivered to the troops by 2031.

Among the currently known prospective buyers for further Boxers are some Eastern European countries as well as Germany and the Netherlands. The Bundeswehr has an as yet unquantified and unspecified demand for vehicles for infantry combat and short-range air defence, among other things, which may be covered between 2023 and 2027. The Netherlands has indicated that the current equipment of 200 boxers is neither quantitatively nor qualitatively sufficient and that a repeat order could be placed in the foreseeable future. Great Britain’s original requirement was for over 1,000 boxers. If the procurement requests can be realized approximately as shown, the production capacities for this decade could be fully utilized and the total production volume could exceed 2,000.

Boxer Concept

The Boxer’s unique selling point is its division into driving module and exchangeable mission modules. This is a basis for flexibility, which is manifested in the increasing number of different mission modules.

Drive module

The drive modules, which were part of the first Boxer, were fitted with stronger armour and mine protection, among other things, during the Afghanistan mission. The drive modules provide the entire vehicle technology for the Boxer, including the drive and chassis as well as mechanical and electrical interfaces for accommodating and operating the mission modules.

With the drive modules, which are the same for all Boxers, it is possible to achieve an equal utilization of the fleet by exchanging drive modules of Boxers with high mileage for drive modules with low mileage. In this way it could also be ensured before an operation/exercise that no scheduled maintenance will be due for the vehicles used in the near future. In the case of longer-term maintenance, the operational drive modules can be used for the most urgently needed capabilities (mission modules).

The Boxer was delivered in its original version (A0) with a gross vehicle weight of 36.5 tons and a 530 kW MTU diesel engine (MTU 8V 199 TE 20). Due to the changed threat and with initial findings from the operational assessment, the mine protection under the hull and in the wheel housings was reinforced. A new driver vision system and the partial stowage of equipment (e.g. tow rope) improve the working environment of the military driver. Modifications to the cooling air and exhaust system help to reduce the signature. With these changes the version designation developed up to A2. Today, this configuration is standard in the Bundeswehr. All vehicles will be retrofitted to this standard.

For Australia, the permissible gross vehicle weight was increased to 38.5 tonnes. This required reinforcements on the axles and, as a consequence, new wheels and more load-bearing tyres. This version of the driving module could be designated A2+.

The UK boxers will be the first to be equipped with a 600 kW diesel engine (MTU 8V 199 TE21, the same as in the Ajax Scout) and will be approved for a gross vehicle weight of 38.5 tonnes. Internally, the driving module will be operated under the A3 version. External characteristics include the new rim-tire combination mentioned above. The specific output increases to 15.6 kW/tonne (A2: 14.8; A2+: 13.8).

The mission modules provide protected cabin volumes from 14 m³ to 17.5 m³ for crews and systems that are equipped mission-specific according to military requirements. Depending on the count, around twenty different variants are currently in use, built or in production.

Mission modules (selection)

– Passenger transport

– Command/Control

– Ambulance

– Infantry combat

– Driver training

The outer dimensions of the mission modules are fixed, only the cabin roof can vary in height (as for example in the wounded transport vehicle of the Dutch). An opening at the front allows access to the driver. Hatch, exit, seats and equipment are mission-specific. OCCAR has referred to a modular installation system, in which elements (mainly COTS/MOTS products) are available in the categories protection, sensors, effectors, C4I, as well as configuration examples for interior and exterior, which can be used to quickly generate mission-specific modules.

The Boxer for UK will have a special feature. For the mission modules (except ambulance) there will be mission kits, which will allow an even more detailed adaptation to the respective task.

The success of the concept with mission modules can also be seen in the fact that new ideas/requirements for the realization of further capabilities based on the Boxer are constantly being presented by the user side. This includes among others

– Reconnaissance and observation with stabilized platform (Joint Fire Support),

– qualified air defence, including against UAV and helicopters (Short Range Air Defence) and

– Infantry combat with manned turret and medium calibre cannon (Heavy weapon platform).

The ARTEC consortia present military customers with proposals for mission modules, some of which are functional demonstrators designed in response to military requirements.

The ARTEC consortia present military customers with proposals for mission modules, some of which are functional demonstrators designed in response to military requirements.

– Remote controlled howitzer 155 mm (RCH 155). A further development could be ready for series production from 2027.

– Rocket launcher to supplement / replace MARS

– Mortar carrier

– Ammunition transporters

– Close-range air defense with cannon

– Laser weapon system for defence against drones and artillery shells

– Bridge laying vehicle with LEGUAN or GECKO bridge

With the only mission module developed outside ARTEC to date, FFG Fahrzeugbaugesellschaft has presented a vehicle for recovery and field repair.

Cooperative operational support

The three Boxer nations have established a Boxer Support Partnership at the NATO Support and Procurement Agency (NSPA). One main task is material management. According to the cumulative demand, the NSPA procures the spare parts centrally and makes them available to the nations. Joint management reduces the number of spare parts to be kept in stock (and thus the capital outlay) and lowers procurement costs by increasing order quantities. If necessary, the nations can “borrow” urgently needed spare parts. The technical team coordinates configuration management and provides logistical and technical data.

Perspectives

After a long start-up period, the Boxer with its modular concept has become a success story. With four user countries and further aspirates in Europe, it can become a European showcase project, from which non-European customers Australia can also benefit. The flexibility of the concept opens up new possibilities for the users to realize capabilities.

With a load capacity of 38.5 tons, the driving module is not yet exhausted. This provides sufficient growth potential for future requirements.

Gerhard Heiming