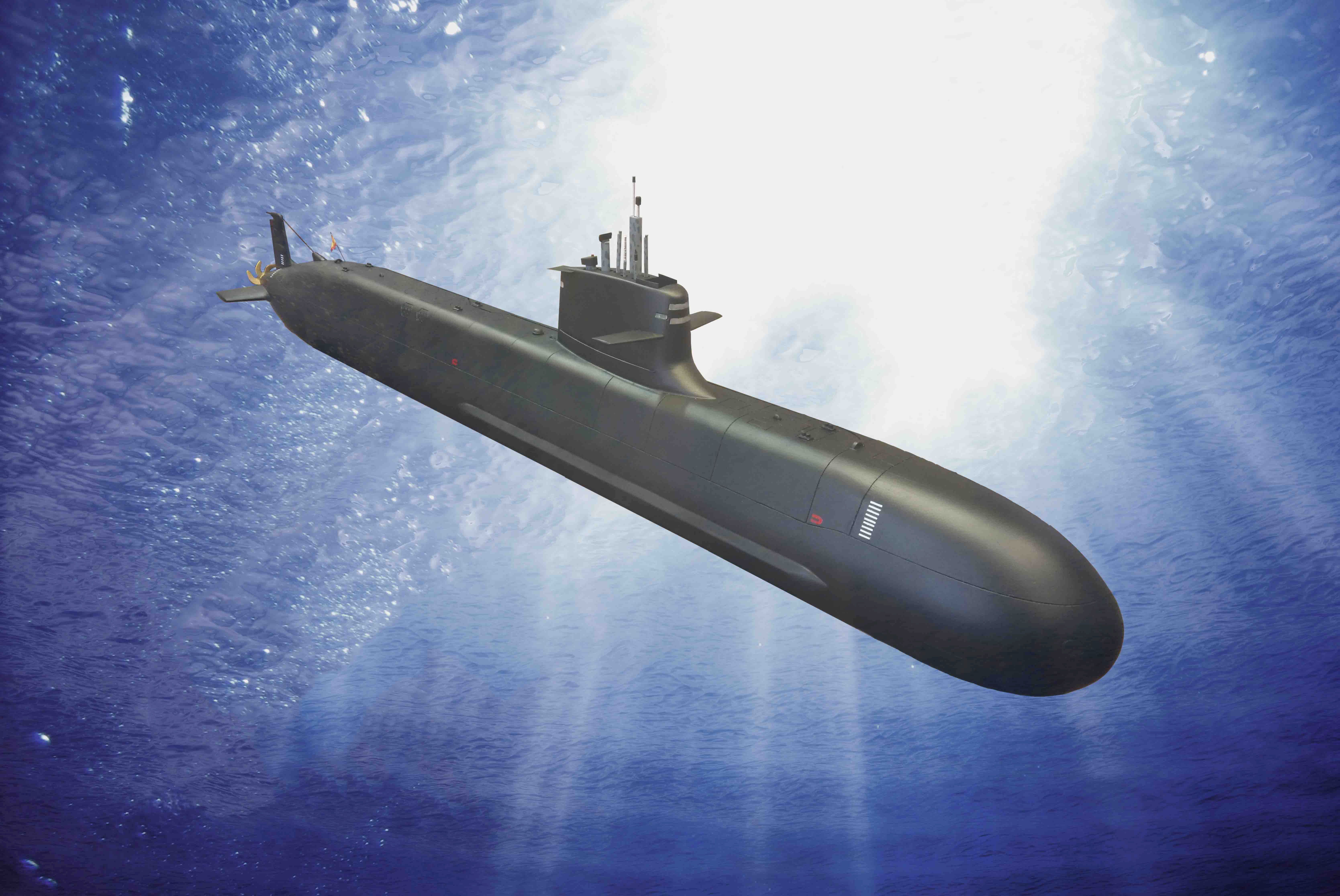

In a video presented during its Euronaval workshop, Navantia explained how the Cartagena shipyard has evolved to adapt to the challenge of building the S80 submarine, the first fully indigenous submarine and the only 3000 tonne Air-Independent Propulsion (AIP) submarine produced worldwide. Investments concerned the physical infrastructure (such as the creation of dedicated workshops and the purchase of robots to increase automation), the digital infrastructure (simulators) and the development of the critical systems to be mounted onboard (combat systems, management systems and communication systems). After a delay in advancements due to Covid-19 (which forced the company to postpone the first set afloat to the beginning of 2021), Navantia has now fully resumed its activities and recovered the delay.

The Bio-Ethanol Stealth Technology (BEST) AIP system is among the key features of this programme, as it provides a submerged endurance of up to three weeks. Questioned on the reasons for this unprecedented choice, shipyard Engineering Director, Germán Romero Valiente, explained that the company chose bioethanol as this is a safe (non-toxic), low-cost solution available worldwide. BEST is at the core of one of the current challenges Navantia is working on, in the form of combination with Li-ion batteries, for which integration on the S80 is under study in collaboration with French company Saft. This feature was not integrated in the current design but is of interest for customers, including the Spanish Navy. Battery retrofitting during overhauls is in the company’s roadmap but will depend on the interest of potential customer navies. Navantia is also working on the integration of Unmanned Underwater Vehicles (UUVs) on its submarines.

Giulia Tilenni