Traditionally an infantry asset, mortar capabilities are evolving both technologically and tactically, delivering new possibilities for mounted and dismounted units and with ammunition and fire control solutions bolstering their operational performance.

Mortars are on the up. New technologies, systems, mobility and tactical thinking mean that the good old mortar, perhaps a little on the back burner earlier this millennium, has found a new place of importance in the inventories of militaries around the world. Traditionally, a key fire-support asset carried and used by infantry typically under the control of battalion commanders, fire support companies have used 120mm or 81mm calibre systems, sometimes installed aboard AFVs or unarmoured vehicles, often detachable for re-deployment on the ground for use by dismounted troops, to deliver critical fire support to friendly forces on the front line. And at platoon and section level, 60mm mortars or less have typically been deployed.

From conventional, manual sighting and laying, to today’s digital systems interconnected via secure data links with laser rangefinders, day/night sighting and navigation information. This transition has made target acquisition much faster and given the mortar crews the necessary ability, in the face of changing operational threats, to perform fire missions in extra quick time, including with multiple rounds simultaneous impact (MRSI) capabilities. Being able to shoot and scoot before the enemy has the chance to locate the mortar position and then respond with counter fire is now critical to survival on the battlefields of today and tomorrow.

With more target acquisition systems and technologies now available and being used by many nations’ artillery units, mortars – previously not the most accurate tool in the toolbox — are also, with some militaries, coming under the control of the artillery, in turn benefitting from the artillery’s highly precise target acquisition data, to become more accurate in the process. But while advances in mortar fire control and associated systems are part of this mortar evolution, ensuring what lands at the other end delivers the desired effect is critical. Hence, mortar ammunition needing to pack the optimum punch as accurately as possible.

This article looks at some of the ammunition systems being manufactured and available to mortar units across NATO and beyond, as well as developments in fire control and aiming systems that can make mortar systems more effective and accurate than ever before.

Mortar Ammunition

A wide range of mortar rounds have been standard fair for years, from traditional high explosive (HE), the most common used to deliver suppressing fire, to smoke, white phosphorous, and illumination rounds.

As the new-found popularity of mortar systems continues, their typically high trajectory is also an ideal factor to exploit with the development of precision-guided mortar bombs that, much like their artillery counterparts, are intended for use against high-value targets with a view to penetrating weaker top armour due to their high, near-vertical angle of attack.

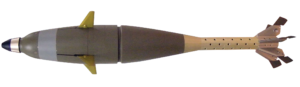

One such system is the General Dynamics Ordnance and Tactical Systems’ 81mm Roll Controlled Guided Mortar (RCGM), which the company calls an ‘affordable, flexible precision-guided (PG)’ mortar round suited to new-age conflicts where there is a greater need for increased precision on target with reduced collateral damage – effectively a portable precision munition for the infantry. The round can be fired from UK L16 and US M252 weapon systems and achieved a circular error probable (CEP) of less than five metres at ranges from 980 to 4000 metres when it was first in development some years ago.

Using a portable GPS setter, target coordinates are programmed into the RCGM, and the multi-mode fuse set manually to the choice of proximity (PRX), point detonation (PD), or point detonation delay (PDD) modes. Once launched, the bomb’s on-board GPS acquires satellites and determines its position and vertical reference. Continuous GPS updates enable the system’s auto-pilot to calculate corrections and send commands to the bomb’s canards, which continuously manoeuvre it toward the target until impact. The round’s accuracy results in a 30% reduction in ammunition resupply logistics as fewer rounds are needed to complete missions.

As it is still in service with an unconfirmed number of nations, including some in NATO, GD also continues to offer the towed, rifled 120mm Expeditionary Fire Support System (EFSS), which was developed in response to the now defunct USMC programme in response to the need for a fire support system lighter, more mobile and internally transportable for missions requiring tactical versatility, speed and close-in fire support. The mortar has an ammunition suite comprising four type-classified munitions: HE, smoke, illumination and practice rounds, which the company says provide greater lethality, accuracy, and range over currently fielded ammunition. The rounds are insensitive munitions (IM) compliant and have an effective range of up to 8.2km. The rounds use standard artillery fuses for point detonation or airburst capabilities. Rifled or smooth-bore ammo can be fired from the EFSS, though rifled typically provides greater stability, accuracy and range over current smoothbore munitions.

The company also offers 60mm and 81mm Mortar Anti-Personnel Anti-Material munitions, which is says deliver up to 100% greater lethality than conventional mortar bombs. The round’s pre-fragmented payload can be tailored to meet specific user requirements to ensure an optimum lethal area against various target sets; GD says this provides the advantage of precision control over the danger zone, giving friendly troops much more responsive fire support in close combat.

The propellants GD’s Ordnance and Tactical Systems division makes for 60mm, 81mm and 120mm mortar systems increments are flash-suppressed and clean burning, which results in minimum residue, flash, and blast overpressure, important for the safety of the mortar team. The company also says that the superior flow characteristics of these Ball Powder propellants enhance efficiency and accuracy of loading operations.

Contract Highlights GMM Prowess

A US$30M, two-year contract awarded in the first half of last year by an undisclosed country in the Asia-Pacific, highlighted Elbit Systems’ mortar ammunition prowess, specifically of its precision-guided Stylet round, the subject of the deal. The bomb is a multi-mode GPS/INS-guided 120mm Guided Mortar Munition (GMM) with a range of 1000-8500m, suited for use by tactical combat units and special forces. It has an accuracy of less than 10m CEP and the company says that it offers an affordable precise solution that is easy and quick to operate, that not only increases operational effectiveness, but also significantly reduces collateral damage.

Stylet is suited for use against high-value targets and features autonomous fire control and multi-target assault capabilities and is effective against infantry and light armoured vehicles at ranges that depend on the 120mm mortar system using the ammo. The mortar bomb features a multi-mode fuse with PD, PDD and PRX operating modes, as well as a five-increment charge/propellant system. Stylet’s blast and fragmentation warhead delivers high lethality and precision with minimal collateral damage. Elbit sees a growing demand for high-precision guided munitions that are also economically efficient.

Stylet is not the only GMM in Elbit’s portfolio and the company has earned a global reputation for innovating precision GMM systems that will meet the operational needs of the modern battlespace, where a precision-strike, first-round capability is needed to support manoeuvring tactical combat units, at the same time as being cost-effective.

As with Stylet, so too are all of its GMMs equipped with a multi-mode fuse and blast and fragmentation warheads. Some also include penetration warheads. These systems significantly enhance firepower at battalion and brigade level, and enable accurate firing to extended ranges with near vertical trajectory at line-of-sight (LOS) and non-line-of-sight (NLOS) targets, in urban or open terrain, and in all weather conditions.

Offering an even greater range capability, the company’s Rapier Long-range GMM can reach distances of 16 km, (depending on the mortar used), with high accuracy, even in severe weather conditions. The GPS/INS round requires no spotting of targets, no meta data, and uses the same multi-mode fuse as Stylet. The round takes 15 seconds to load and has a six-increment charge system.

Iron Sting is Elbit’s 120mm Laser and GPS GMM, which can be fired to ranges from 1 km to 12 km, depending on the mortar tube, and has three modes of operation: GPS/IMU, SAL+GPS/IMU and SAL+IMU. This versatility provides robust capabilities in all battlefield scenarios. Iron Sting features a seeker laser sensor capable of operating with standard pulse (NATO STANAG 3722) and an encoded CW laser diode (lightweight and low-cost, suitable for small drones and UAS). The warhead is capable of penetrating double reinforced concrete with a blast and fragmentation effect. The mortar bomb features the same multi-mode fuse as mentioned above. With no meta data required, loading time of the 10. 8kg round is 15 seconds.

As with the precision-guided kits that now exist to convert artillery rounds into precision-guided munitions, Elbit has its own Laser and GPS-guided Mortar Kit (LGMK), which converts existing 120mm standard mortar bombs into guided ammo. The LGMK enhances the ‘dumb’ round giving it a wide field of view and a moving target capability for precision use against soft or lightly armoured targets, as well as targets in urban environments where providing first-round capabilities and minimum collateral damage is crucial. The solution is compatible with STANAG 3733 NATO laser designation. Elbit’s family of mortar ammunition extends across all calibres and includes a wide range of standard HE, illumination, smoke and training rounds, as well as longer range HE rounds and other specialised munitions.

Pedigree in All Areas

One of the leading suppliers of mortar ammunition to military forces internationally is Hirtenberger Defence Systems (HDS), which makes mortar bombs – it has been making smooth-bore mortar bombs for over 50 years – amongst a wide range of mortars and other mortar-related systems, for 60mm, 81mm and 120mm mortars. A key feature of the company’s munitions is being able to withstand the harshest, hostile environments without compromising safety and without lessening the combat effectiveness of the ammunition. As a result, its IM mortar rounds are well received worldwide. Indeed, in the first half of 2019, HDS was awarded a contract by the Dutch MoD for the supply of insensitive 60mm mortar ammunition for delivery to its armed forces up until 2024, with a further two-year option under the terms of a frame agreement. The company is also in the process of refurbishing 70,000 rounds of old 120mm mortar ammunition for Germany’s Bundeswehr. The munitions, which had been in danger of becoming obsolete, will have their charge systems replaced and be ready for use by 2026.

Taking its 60mm mortar ammunition family as an example, the company’s current range of projectiles include a 60mm practice round Mk2 with inert filler though delivering terminal and impact effects and signature for training purposes. Its 60mm white phosphorous SMK-WP Mk2 round comprises a NATO-qualified WP filler that produces a rapid smoke screen, though rivalled in speed of creating its smoke screen by the company’s 60mm SMK-TTC Mk2 round with its Titanium tetrachloride filler also delivering very rapid smoke, though in this case, of ‘cold’ smoke. HE rounds for 60mm systems include the 60mm HE-TNT Mk2 PD and PRX bombs, both of which produce up to 5,000 fragments (see below). All the above weigh in at 1.79 kg. Also for 60mm systems are HSD’s pyrotechnic ammunition with canister form ballistics. These include the red phosphorous SMK-RP Mk2 used to generate smoke screens that last up to 90 seconds and two illumination rounds: the ILL-VIS Mk2 with visible luminosity of 350,000cd that lasts 40 seconds during a 5 m/s descent, and the ILL-IR Mk2, which provides high infra-red emissions and low visible light emission. A similar range of ammunition is available for both 81mm and 120mm mortars.

On the subject of fragmentation, what HSD calls its ‘revolutionary, new’ CONFRAG technology is said to ensure that its bombs are more precise in their delivery of lethal fragmentation effects than other HE. CONFRAG controls the mass, velocity and distribution of fragments and apparently surpasses the current global standard of natural fragmentation, which produces fragments differing in size, mass and shape, therefore, with lower lethality. CONFRAG-delivered fragments are said, by HSD, to have much more energy, penetration power, and a greater coverage area resulting in increased lethality.

New Materials in Production

With its mortar systems in use in 35 countries around the world another player with a pedigree in all areas and offering munitions for 60mm, 81mm and 120mm mortars is Expal; the company provides ammunition in HE, IM, HC, WP, RP, ILL, IR and TP configurations qualified and compatible with all NATO smoothbore systems. It develops, manufactures, and integrates its own fuses, primers, propellants and other key components in house; it is Expal’s core competence and experience in explosives and energetic materials technologies that sets it apart from many. The company’s recent work adapting new materials and processes to improve conventional ammunition, including mortar bombs, is a milestone. Expal has researched the use of new polymer-based materials to replace metallic materials, where the former exceeds and improves the functionality and characteristics of original systems. In addition, with the increasing industrial use of 3-D printers in which such polymers can be used, a revolution in the generation of 3-D prototype munitions is possible. The company has also carried out a study on the adaptation of plastic materials in candles for illumination mortar bombs; traditional production involves a series of manual processes that require exhaustive controls to guarantee correct functioning; an inhibitor adhered to the internal walls of the round’s canister, helps avoid corrosion and works as an insulator when in operation. Using plastics, however, the new adaptation consists of designing a body that integrates the insulation, enhancing candle performance with a new material that’s chemically compatible and capable of withstanding the extreme forces and handling experienced during loading and firing. Different materials were selected for this R&D that could be manufactured both by injection and 3-D printing and offer characteristics such as high mechanical resistance, very long life, lightweight, lower cost, as well as being conductive and anti-static. The company intends to apply these new materials and processes to other munitions and products, including its wider range of mortar bombs, to help reduce weight of payloads or internal parts, and to enhance external ballistics. These developments are also set to improve manufacturing and production processes overall.

to ranges from 1km to 12 km.

Single-Calibre Focus

With its focus on 81mm, BAE Systems has an effective range 81mm mortar bomb variants used by the British Army and other armed forces around the world with a variety of weapon systems. Currently, the company says that its engineering team is developing several improvements to these bombs to increase effectiveness and operational safety for users, which include IM compliance, so that mortar crews will be at a much lower risk of enemy fire triggering an explosive chain reaction in mortar bomb stockpiles on their position. In addition, precision guidance is being researched and the company says that it now has a fully developed mortar guidance system, which uses GPS and fins/canards built into the fuse to provide two-dimensional course correction.

A further line of research is into preformed fragmentation. Even though the company’s HE L41A4 round with Mk4 charge system is said to provide optimised fragmentation from its spheroidal cast-iron bomb body, BAE Systems is testing preformed fragmentation that has the potential to increase the area effect and offensive capability of the 81mm HE bomb.

The current L41A4 HE round uses PD and PRX fuses and has a range up to 5,375m. Other 81mm rounds include red and white phosphorous smoke bombs, and two illuminating rounds, one which is IR Illuminating. Interestingly, the company says its RO 04-04A1 red phosphorus smoke variant gives longer lasting and more effective smoke production with lower toxicity than white phosphorus, and uses 36 pellets that disperse and sit above ground producing an effective smokescreen over a wide area in 120 seconds out to ranges up to 5,375 metres.

Mortar Fuses

Complementing any effective mortar round is an effective fuse and expertise in fuse technologies doesn’t come much deeper than that from Junghans Defence; from g-hardened fuses and ignition systems, to mechanical fuses and fuse components including micromechanical subassemblies and mechanical safety and arming devices, and much more. Junghans’ R&D in fuse technology, including for its mortar rounds, is constantly innovating to develop solutions, which may be required in the future to satisfy emerging operational needs. Indeed, the company is currently working on a new proximity fuse called FLAME, although not yet in service. This new multi-option PRX fuse will have four modes of operation, these are: PRX high altitude / PRX low altitude, PD, and PDD. PDSQ (super quick) is also in development as a capability. The new fuse will have an IM firing train and will be both EU REACH regulation and STANAG 4187 compliant.

As for Junghans’ many other mortar round fuses, the family includes both DM93 (and a latest version the DM183) and L171A2 mechanical mortar fuses, which are in service in the UK. The former, the DM93 / M776 Mechanical Time Super Quick (MTSQ) Mortar Fuse is a mechanical time fuse with an additional impact mode, proven worldwide for use with illuminating and smoke rounds and suited for smooth-bore calibres between 51mm to 120mm. The safety devices of the DM93 (M776) fuse comprise a safety pin and a launch-pulse safety system, which ensures the fuse will react on impact but not before. It complies with MIL-STD 331C, STANAG 4157, AOP20, MILD-STD and STANAG 4187.

Junghans’ DM 111A4 / L127A4 PD Mortar Fuse is for use with HE, TP and smoke and has a highly sensitive impact device and can be set to two different modes: super quick and delay achieving a proven reliability better than 99.5%; it can be used with fin-stabilized 51mm to 120mm mortar bombs. (A latest version, the DM111S, is also available).

Mortar Fire Control and Aiming Remarks

The accuracy of mortars is certainly improving as a result of latest precision ammunition developments, round design and propellant charge innovations. But without accurate and speedy fire-mission data and coordinates, communicated efficiently together with the ability to lay the mortar quickly, all the above will be of little comfort to the forward troops calling for accurate, suppressing fire in the face of an advancing foe.

Directly networked with computerised fire control and navigation systems, latest vehicle-mounted mortars can be laid on target quickly and, using powered traverse and elevation, can deliver rounds on target rapidly. This enables mortar crews to bug out to another firing position before enemy locating troops can identify their position — advanced digital fire control will help ensure any counter fire lands on empty positions. The turntable-mounted Cobra 120mm mortar system from RUAG Defence, for example, now has an all-electric traverse and elevation system with a load-device and a computerised FCS. And the Spanish Alakran 120 mm Light Mortar System (LMS) from Everis Aerospace and Defense and New Technologies Global Systems (NTGS), which can be integrated into the rear of a variety of vehicles such as a Toyota 4×4 Land Cruiser, is connected to a computerised FCS. This enables rapid laying of the weapon once lowered to the ground via an electro-mechanical system.

Along with MFCSs, a number of mortar systems are now adopting the use of muzzle velocity radar — MVR. In the case of the CARDOM 10 120mm recoil mortar from Elbit, each system will have an MVRS-700SC MVR fitted under the barrel from Danish maker Weibel. The MVR measures factors such as temperature, humidity and barrel conditions, all of which will impact the final MV of a departing mortar bomb. Data from the MVR is fed to the FCS with which it is integrated so that individual mortar settings can be adjusted accordingly to ensure accurate final elevation and bearing and fuse settings are entered resulting in as accurate a fall of shot as possible.

CARDOM’s FCS is based on NATO’s S4 software and with inputs from both the MVR and additional meteorological data, can deliver a very accurate result, eliminating the need for adjustment of fire and enabling fire for effect from the very first rounds. This FCS-enabled accuracy is crucial in keeping time on position to a minimum; missions can be fired and mortar crews move before counter-fire has a chance of success. CARDOM 10 uses an auto-laying system; an electric drive delivers the weapon to the correct elevation and bearing/traverse, as well as being fast enough for the system to be capable of delivering MRSI. The FCS is networked with the parent unit’s battle management system and fire mission orders are now typically received through digital communications direct from forward observers into the FCS. The forward observer can also still use voice comms via tactical VHF radio to the mortar team. [Elbit Systems of America was awarded a deal in 2017 to provide mortar fire control systems for the US Army consisting of the Mortar Fire Control Systems Mounted (MFCS-M), Mortar Fire Control Systems Dismounted (MFCS-D), and a lightweight handheld mortar ballistic computer.]

In September last year Expal launched its E-COMPAX system, an electronic aiming device for the provision of firing aiming data to mortars, covering metrics such as orientation and elevation even in a denied or degraded GPS environment. The system reduces the time to firing to only 30 seconds and the after-firing adjustment to less than five seconds. An easy interface and software implement all necessary functionalities to perform aiming, either in a standalone mode on its own tablet, or integrated into an FCS computer, such as Expal’s own TECHFIRE system, which can be used and integrated with the company’s EIMOS Integrated Mortar System. TECHFIRE enables highly precise firing data to be provided to the mortar including information from unmanned forward observers, such as the company’s UAV Shepherd-Mil, and is totally integrated from the sensor to whichever mortar system it’s integrated with. It automates and accelerates all tasks related to direct or indirect fire missions, whether in a single mortar, or in a unit, increasing precision and control over supporting fire processes. The intelligent systems developed for TECHFIRE integrate an automatic target acquisition system to improve precision and its software enables real-time ballistic correction, meteorological compensation, and aiming adjustments. TECHFIRE (also suited for use with artillery) is also compatible with a wide range of mortar ammunition and their associated firing data tables. It can also link with a variety of communications and data management systems, as well as laser rangefinders. Through its interactive and user-friendly graphical interface, the system enables operators to deal with all kinds of fire control, process data, and exchange operational information and orders among key stakeholders in the mortar mission command chain.

The ‘Mortar Company’ as some refer to them, Hirtenberger, also offers an MFCS solution in its portfolio comprising a forward observer computer responsible for detailing observer locations, fire mission planning functions, introducing variable correction options into a mission, as well as conducting up to four simultaneous missions. The FCS takes into account weapon position information, aiming data, has an integrated mapping function including satellite views. Complementing the forward observer computer on the weapon position are the mortar computer and a GPS-enabled military handheld computer. The former performs multiple weapon control functions, keeps track of ammunition, assesses calculation options and performs fire plan functions.

Not to be missed, the Morzen Mk3 portable handheld computer from fire control experts, Maszengrange, provides rapid and accurate ballistic firing data for light and heavy mortars in man-portable, towed or self-propelled configurations. Designed as a flexible standalone system, the Morzen Mk3 is typically deployed at the mortar command post as the primary or back-up ballistic computer or alternatively at the weapon platform to perform ballistic calculations, providing significant redundancy to the user. The rugged, lightweight system incorporates an intrinsic, high-capacity power cell and an effective, reliable charging system. The company also offers the Morfire MFCS, which enables effective, responsive and accurate fire and is capable of providing rapid firing solutions to all known smooth bore mortars. Morfire links observers with command post nodes and weapons and comprises a MFC platform, a Mortar Command Post (MCP) platform and a Mortar Data Unit (MDU) platform. Voice and data communications from MFC to MCP is by Combat Net Radio, and voice and data communications from the MCP to the MDU is by data-enabled personal role radios.

Last but by no means least, Turkish company, Aselsan, offers an integrated MFCS, which includes a Fire Control Computer, an Inertial Navigation System (INS), and an MVR. The system enables rapid deployment and continuous location by means of an INS and provides rapid and accurate ballistic calculation using data from the MVR and forward observers via digital radio; it has a menu-driven graphical user interface and battlefield information is also displayed on digital maps.

Tim Guest is a freelance journalist, UK Correspondent for ESD and former officer in the UK Royal Artillery.

![2025 in the Western Balkans: A year-end SITREP Soldiers from the Czech company, part of the EUFOR Multinational Battalion, conducted a series of joint training exercises in Mostar alongside operators from Bosnia’s State Investigation and Protection Agency (SIPA). [EUFOR BiH]](https://euro-sd.com/wp-content/uploads/2025/11/Handshake_EUFOR-BiH-218x150.jpg)

![Stratus symbol Initially deployed during Operation Granby, the United Kingdom’s contribution to Operation Desert Storm in 1991, the RAF’s air-launched anti-radiation missile proved to be a radar killer. The missile remained in service, and in the RAF’s inventories, until 2013. [Thomas Withington]](https://euro-sd.com/wp-content/uploads/2025/11/ALARM-Thomas-Withington-Kopie-218x150.jpg)

![Baltic Security: SITREP : US Soldiers assigned to 3rd Battalion, 8th Cavalry Regiment, 3rd Armored Brigade Combat Team, 1st Cavalry Division, Task Force Iron, fire a M1A2 Abrams tank during a live-fire demonstration for Iron Defender 25 at Orzysz Training Area, Poland, on 17 September 2025. [US ARNG/Sgt Eric Allen]](https://euro-sd.com/wp-content/uploads/2025/11/Abrams-firing_US-ARNGSgt-Eric-Allen-Kopie-218x150.jpg)

![Hybrid navies: Integrating uncrewed capability into carrier strike The US Navy (USN) carrier USS John C Stennis (left), the French Navy carrier FS Charles de Gaulle, and elements of their strike groups are pictured sailing together in US Fifth Fleet’s area of operations. The US, French, and UK navies are all developing ‘hybrid’ crewed/uncrewed mixes for their carrier airwing capability. [US Navy]](https://euro-sd.com/wp-content/uploads/2025/09/2-HST-CdG-USN-Kopie-218x150.jpg)