Interview from Curtis Hand

If you attend a major international defence trade exposition almost anywhere in the world, then you will witness a stultifying number of different demonstration videos that promote major weapon systems with epic levels of fire power. The number, dimension and sound of these videos are overwhelming on a typical exhibition day. Few wonder about where the “demos” took place or how the countless frames per second videos were captured to allow potential weapon system customers to see, hear and virtually experience the demo to best understand its advantages in the evolving battlespace.

We caught up with Col Stefan Krol (Ret., Sweden), the president of Bofors Test Centre who oversees the facility where a number of defence companies test, demonstrate and film their weapon systems and military platforms. The Bofors Test Centre’s expert technicians rigorously challenge the performance of a customer’s product here, “putting it through hell” as Col Krol guarantees. The Test Center hosts unique demonstration events for customers and their clientele and can assess, examine, analyse and certify products or systems for various defence companies and material organisations.

European Security & Defence (ESD): How did the Bofors Test Centre come into being as an independent business?

Stefan Krol (KROL): To make a long story short… Once upon a time, in the good old glory days, there was a company called Bofors who manufactured everything from toothpaste to self-propelled howitzers.

When the cold war was over and the world was heading for eternal peace the business opportunities decreased and Bofors was split up into three major parts: the artillery and naval gun division which nowadays are owned by BAE Systems, the shoulder launched weapons and missile division which is now under Saab’s ownership and finally the high explosives and propellant plant which today belongs to Eurenco. When this happened all of these companies required the extensive testing capacities that the proving ground department of Bofors was able to provide.

In order to give all of them access to the proving ground, Bofors Test Centre was created as an independent company with the purpose of serving our owners with the best testing facilities possible for weapon systems and ammunition. Since this is a high ambition level which is costly to maintain and improve it was decided that Bofors Test Centre also should be open for other customers (i.e. the competitors of our owners). Today we perform tests for most of the big international weapon systems and ammunition manufacturers; especially those who are in the field of artillery, mortar, naval guns and main battle tank systems.

ESD: How large is the site / facility?

KROL: Our proving ground area is about 100 km2, approximately 30 km in length with a maximum indirect firing distance of 25 km. A wonderful place to study, evaluate and qualify military equipment. Especially the kind of equipment which contains energetic materials.

ESD: What is the range and depth of testing and demonstrations that take place there?

KROL: To cover our owners’ and customers’ needs to show their products for their end clients we can perform everything from very technically orientated demonstrations to complete battle scenarios. We use to say that the only limit for what we can do is our customers’ imagination and budget. An odd thing in this game is that we have even performed a demonstration (after we first performed a complete internal, external and terminal ballistics study) of a 17th century naval cannon for the famous Vasa warship museum in Stockholm. A video from that demonstration can be found on our website www.testcenter.se as well as on our YouTube channel.

ESD: How does the Bofors Test Centre work with customers to capture test and demo results on video?

KROL: We have a great range of state of the art cameras with which we can film both in high definition as well as in high speed capturing a very large amount of frames per second which lets the viewer assess all details in extreme slow motion with an astonishing quality of each frame. Since this technology is evolving rapidly we invest a lot of money in new cameras and associated equipment constantly to be at the front edge of what could be performed.

ESD: What is the maximum Frames Per Second (FPS) capture that is available from the Bofors Test Centre? What other media is available for customers to help them show what their product or system does or can handle?

KROL: A tricky question which is difficult to answer due to the fact that the maximum FPS you can get is connected to a lot of variables like the frame resolution, the quality of the frames, the surrounding light conditions and so on. Other supporting equipment often used to prove that a system works as it is supposed to do could be radars, optical tracking platforms and IR-cameras. Most of the time in combination with various sorts of measurement equipment for pressure, temperature and strain etc.

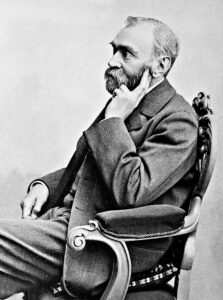

ESD: For the benefit of our readers, what does “Bofors” mean and how is the Bofors Test Centre legacy (per se) related to Alfred Nobel, the founder of the Peace Prize?

KROL: For us “Bofors” means quality, superb quality. Without any doubts. All of this related to the great legacy of the Bofors company which was started as a blacksmith already in 1646 and with their first firing range built in 1886. The war fighter shall know that the products he or she are using in order to maintain peace and in which they keep the trust of their lives always shall work the way they were designed to work. As a former Colonel in the Swedish Army I know that in the battlefield there is no room for equipment failure. We are there to help our owners and customers to provide our soldiers with such equipment. Personally I think that the old saying “Si vis pacem, para bellum” (“if you want peace, prepare for war”) fits well in what we do and in Alfred Nobel’s ideas of a world in peace for which he founded the Peace Prize.

ESD: Tack så mycket, Överste Krol.