Ammunition Standardisation and Interchangeability

Thomas L. Nielsen

In this article, Thomas L. Nielsen examines in detail the core concepts and requirements central to the standardisation and interchangeability of ammunition, from small arms to tank guns.

Most people, especially those involved in military logistics, will have a reasonable idea of what the words ‘standardisation’ and ‘interchangeability’ mean, and why they are important. Nevertheless, before we further delve into these two interlinked issues with regards to ammunition, it would perhaps be beneficial to define more precisely what we mean.

Credit: 10th Army Air and Missile Defense Command

The NATO AOP-38 “Specialist Glossary of Terms and Definitions on Ammunition Safety” defines “interchangeability” as:

- “The ability of one product, process or service to be used in place of another to fulfil the same requirements.”

- “A condition which exists when two or more items, in a specified life cycle and environment, possess such functional and physical characteristics as to be equivalent in safety, performance and durability, and are capable of being exchanged one for the other without alteration of the items themselves, or of adjoining items, except for adjustment, and without selection for fit and performance”.

Neither the above NATO document, nor NATO AAP-6 “Glossary of Terms and Definitions”, provide a definition of ‘standardisation’, but the Merriam-Webster online dictionary gives, as one of the definitions of “[to] standardize”: “to compare with a standard: to determine the strength, value, or quality of (something) by comparison with a standard”.

The links between the two terms are also evident: the definition of interchangeability refers to the ability to “fulfil the same requirements”. These requirements must of course be stated and agreed upon, such as in a standard. Conversely, standardised characteristics are most often employed to ensure a degree of interchangeability, whether for ammunition, batteries, bolts, or mobile phone chargers.

There is a third commonly encountered term regarding interchangeability that we will address, and that is “3F”, or “Form, Fit and Function interchangeable”. A number of definitions exist for this term, but one of the most useful is:

“Form: the physical properties of the item, such as shape, size, mass, dimensions, etc.

Fit: the ability of an item to physically interface or interconnect with or become an integral part of another assembly.

Function: the action that an item is designed to perform.”

It can be seen from the above that 3F is very similar to the second AOP-38 definition of “interchangeability” given above and, in the following, no distinction will be made between these two definitions.

As such, these are the definitions we will use as we move forward: “Interchangeability” means “able to fulfil the same requirements”, and “standardisation” means “to conform to a published, agreed-upon set of characteristics in terms of physical properties and performance”.

The following will refer mainly to small arms ammunition, although the principles discussed apply equally to other ammunition types and, indeed, most types of materiel.

Standards, Standardisation and Interchangeability

With regards to small arms ammunition, there is an important distinction between civilian and military standards and, by inference, their respective significance for interchangeability.

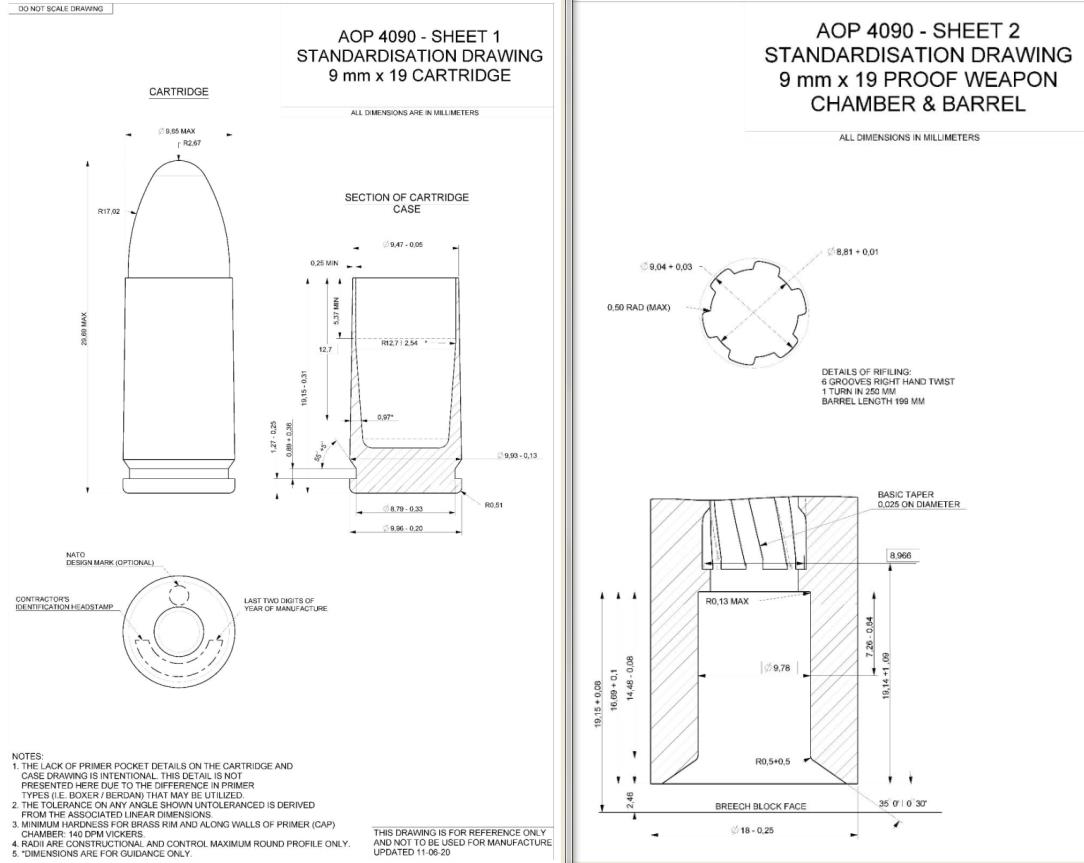

The standards used for civilian ammunition and weapons are the ‘Commission Internationale Permanente pour l’épreuve des armes à feu’ (C.I.P.) in Europe and, in the US, the equivalent ‘Sporting Arms and Ammunition Manufacturers’ Institute’ (SAAMI) standards. These organisations issue standards for small arms and small arms ammunition, and both the organisations and their standards are focused on interchangeability only to the extent required to ensure that the ammunition and weapon combination is safe for the user. As such, their standards define only the external dimensions for cartridges, and the internal dimensions of the weapon chamber, for each standardised calibre, as well as the permissible maximum chamber pressure and the associated proof pressure load. Whether the ammunition in question functions reliably in a given weapon, or whether it is suitable for a given task, is not covered by these standards.

The military standard, in this case published by NATO, for small arms ammunition is significantly more extensive. The standard in question is the Allied Engineering Publication no. 97 (AEP-97) “Multi-calibre Manual of Proof and Inspection for NATO Small Arms Ammunition” (M-CMOPI). Referring back to the previous chapter, the M-CMOPI purpose is defined as (author’s highlight) “to prescribe standardised proof and inspection procedures for multiple calibres of NATO small arms ammunition to ensure uniform test methods and comparable test data to ensure functional interchangeability on the battlefield.” In other words, the express purpose of this standard is to ensure battlefield interchangeability. In order to ensure this, the standard defines not just dimensions and maximum pressure for each calibre, but a range of 16 different performance-related tests, as well as the relevant “pass” criteria for each test.

NATO Small arms ammunition interchangeability

Small arms ammunition interchangeability is a significant issue for international, military organizations such as NATO, where a large number of nations are expected to cooperate effectively during training and on the battlefield. In order to simplify already complex logistics, it is extremely helpful if one country’s small arms ammunition can be used safely and effectively by other countries.

Credit: (NATO)

This means that, unlike the civilian standards referenced above, “functional interchangeability” includes a wide range of factors in addition to safety. The complete list of tests included in the AEP-97 standard comprises:

Electronic Pressure, Velocity and Action Time (EPVAT) Test – verifies chamber pressure and, where relevant, gas port pressure generated by the ammunition, as well as muzzle velocity and action time (the latter defined as the time between the firing impulse (hammer/striker hitting the primer) and the projectile exiting the muzzle).

Climatic Storage Test Procedures – this test repeats some of the listed tests under extreme climatic conditions, to ensure the safety and functionality of the ammunition under these conditions.

Function and Casualty Test Procedures – here, the ammunition is tested in several so-called ‘NATO Nominated Weapons’, to verify reliability.

Link Test Procedures – this test is performed on linked ammunition for machine guns, to verify the physical strength of the links.

Barrel Erosion Test Procedures – verifies that the erosion of the weapon barrel caused by firing the ammunition is within defined limits, and that using the ammunition does not unacceptably shorten the barrel life.

Smoke and Flash Test Procedures – verifies that the ammunition does not produce excessive smoke or flash on firing.

Precision Test Procedures – verifies the precision of the ammunition.

Terminal Effects Test Procedures – verifies the terminal ballistics, in this case hard-target penetration, of the ammunition.

Trajectory Match Test Procedures – verifies that the ammunition matches the ballistics of designated NATO reference ammunition, ensuring that a weapon will shoot approximately to the same point of aim with the ammunition being tested.

Tracer Performance Test Procedures – verifies the performance of tracer ammunition, in terms of tracer visibility and duration.

Residual Stress Test Procedures – test for residual stress in the cartridge case. This is important to the robustness and longevity of the cartridge case, since excessive residual stress can lead to cracking and corrosion.

Primer Sensitivity Test Procedures – verifies that the sensitivity of the primer used in the ammunition falls within defined limits, for instance, testing how hard an impact is required to initiate the primer. This is important not only for safety, but also to ensure reliable ignition in the weapon.

Bullet Extraction Test Procedures – verifies the force required to pull the projectile from the case.

Propellant and Primer Test Procedures – establishes the chemical composition of the primer compound and the propellant. The result is used for future reference.

Waterproof Test Procedures – verifies the waterproofing of the cartridge.

Cook Off Test Procedures – verifies that cartridges with incendiary or explosive projectiles will not ‘cook off’ (self-ignite) in a hot weapon chamber.

The NATO M-CMOPI covers those calibres that are considered NATO standard, which as of September 2022 included:

- 6 mm × 30

- 7 mm × 28

- 9 mm × 19

- 56 mm × 45

- 62 mm × 51

- 7 mm × 99

The NATO working group responsible for the M-CMOPI continuously evaluates other calibres for potential inclusion in the standard, if they are considered to be in sufficiently widespread use within the alliance.

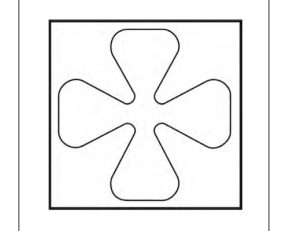

NATO operates two test centres that perform independent testing of ammunition against the above standard, one in the US and one in the UK. If a specific ammunition passes all the M-CMOPI tests, it is awarded a so-called NATO Design Number, as evidence that it has passed all tests for interchangeability. Furthermore, the producer of the ammunition may now include the NATO ‘cloverleaf’ interchangeability symbol in the ammunition headstamp and on the packaging.

Credit: (NATO)

It is, in this respect, important to point out, that it is up to the individual NATO member states to submit ammunition to the test centres for interchangeability testing – ideally, members will submit any new ammunition they include in their stockpile. Also, once an ammunition has been awarded a NATO design number, the producer must regularly submit production samples for repeat testing, to ensure that production ammunition continues to meet the requirements of the M-CMOPI.

Other weapon types

Moving from small arms to larger calibres, the situation with regards to standardization changes somewhat. A practical, performance-based standard, such as the above M-CMOPI, must necessarily allow a certain degree of variability between individual ammunition lots, and such variability is known and accepted for small arms ammunition, where engagement ranges are relatively short, and where we are talking about ‘battlefield interchangeability’. However, similar variability would be unacceptable for long-range, large calibre weapons such as tank guns and artillery. For this reason, the most common procedure for large-calibre direct and indirect fire weapons and ammunition is to perform a qualification test in each case. This requires a test of a specific ammunition in a specific weapon to verify safety and functioning, and to develop the necessary ballistic calculations to ensure successful impacts on targets at ranges measured in kilometres.

This does not mean that there are no standards for larger calibre weapons and ammunition. For example, there is a NATO standard for 120 mm smoothbore tank ammunition (STANAG 4385), is comparable in principle to the M-CMOPI. There is also STANAG 2928, and the associated AOP-6 Vol. 1, “CATALOGUE OF AMMUNITION HELD BY NATIONS THAT SATISFY INTERCHANGEABILITY CRITERIA OF FORM, FIT AND FUNCTION ONLY”. The latter is essentially a cross-referenced ‘catalogue’ of ammunition types that have been shown to be 3F interchangeable, either through standardisation (as for small arms ammunition), or through qualification testing (for larger calibres).

The ultimate purpose of these documents is still to ensure the maximum degree of interchangeability of ammunition within NATO, regardless of the process used to determine this quality.

Advantages of Standardisation

The advantages of standardisation, in terms of safety and interchangeability, should be evident from the above. Standardisation ensures that ammunition A, of a particular calibre, will function safely in weapon B of the same calibre. The expanded interchangeability testing used by NATO will ensure that a given ammunition will not only function safely, but will also perform adequately, and the ability to exchange ammunition between nations has significant and obvious logistical advantages.

Disadvantages

Just as standardisation has advantages, it also comes with disadvantages. Specifically, standardisation by its nature imposes limits on evolution and improvements to both weapons and ammunition, if both need to conform to existing standards.

An example from the world of small arms ammunition is the 5.56 mm × 45 cartridge. During military operations in Iraq and Afghanistan, critique was levelled at this cartridge, especially in terms of terminal ballistics and long-range performance. The SS109 projectile of the 5.56 mm × 45 NATO cartridge, as standardised via the NATO M-CMOPI, weighs around 4 g, and is fitted with a steel penetrator in the tip of the projectile. One immediate solution to increasing the performance of the 5.56 mm × 45, especially at range, would be to use a heavier projectile, and armies around the world have reported improved performance using cartridges with 5 g projectiles. However, due to the requirements in the M-CMOPI for ballistic match to a NATO SS109 reference cartridge, such improved ammunition is unlikely to meet the requirements of the standard and, as such, cannot be qualified for interchangeability, at least not as the standard is currently written. Similarly, experiments with using alternative cartridge case materials, such as aluminium, steel and polymer, could quickly run afoul of the standard.

Conclusion

For joint military operations, there can be no doubt that standardisation and interchangeability are force multipliers of the first order, not just for ammunition, but for almost any item of supply, and NATO has done, and continues to do, considerable work to ensure this.

However, this should not blind us to the potential disadvantages, in terms of limiting improvements and crimping the introduction of technological advances, and we should do our best to create and update relevant standards with this in mind.

Thomas L. Nielsen