More details have been released about the work taking place to deliver a flying combat air demonstrator under the Tempest programme, which will ultimately deliver a next-generation supersonic stealth combat aircraft for the UK, Italy and Japan through the Global Combat Air Programme.

“The Flying Demonstrator programme is a remarkable effort to design and build a supersonic stealth jet that will prove integration and develop our national skills, while providing data and learning in support of Tempest entering service by 2035,” Richard Berthon, Director of Future Combat Air at the UK Ministry of Defence (MoD), was quoted as saying in a 14 June 2023 press release by BAE Systems. “Today, for the first time, we are able to lift the lid on some of the key work that is taking place on this important programme. Tempest is no longer just an idea or concept on a computer; our industry partners have made real, tangible progress and are bringing the programme to life through innovative projects, such as the flying demonstrator.”

BAE Systems stated in its press release that, at a brand new facility at its site in Warton, Lancashire, test pilots from BAE Systems, Rolls-Royce and the Royal Air Force (RAF) have already flown more than 150 hours with the demonstrator aircraft in a new bespoke simulator, which the company said is “providing crucial evidence to support flight trials”.

“In a first for military aircraft design, BAE Systems’ engineers have used auto coding to create safety-critical systems software in a matter of days rather than weeks,” BAE Systems stated. “This enables rapid assessment of the flight control systems during more complex flight manoeuvres, with the simulator capturing crucial data about how the jet will handle and perform, years before its first flight.”

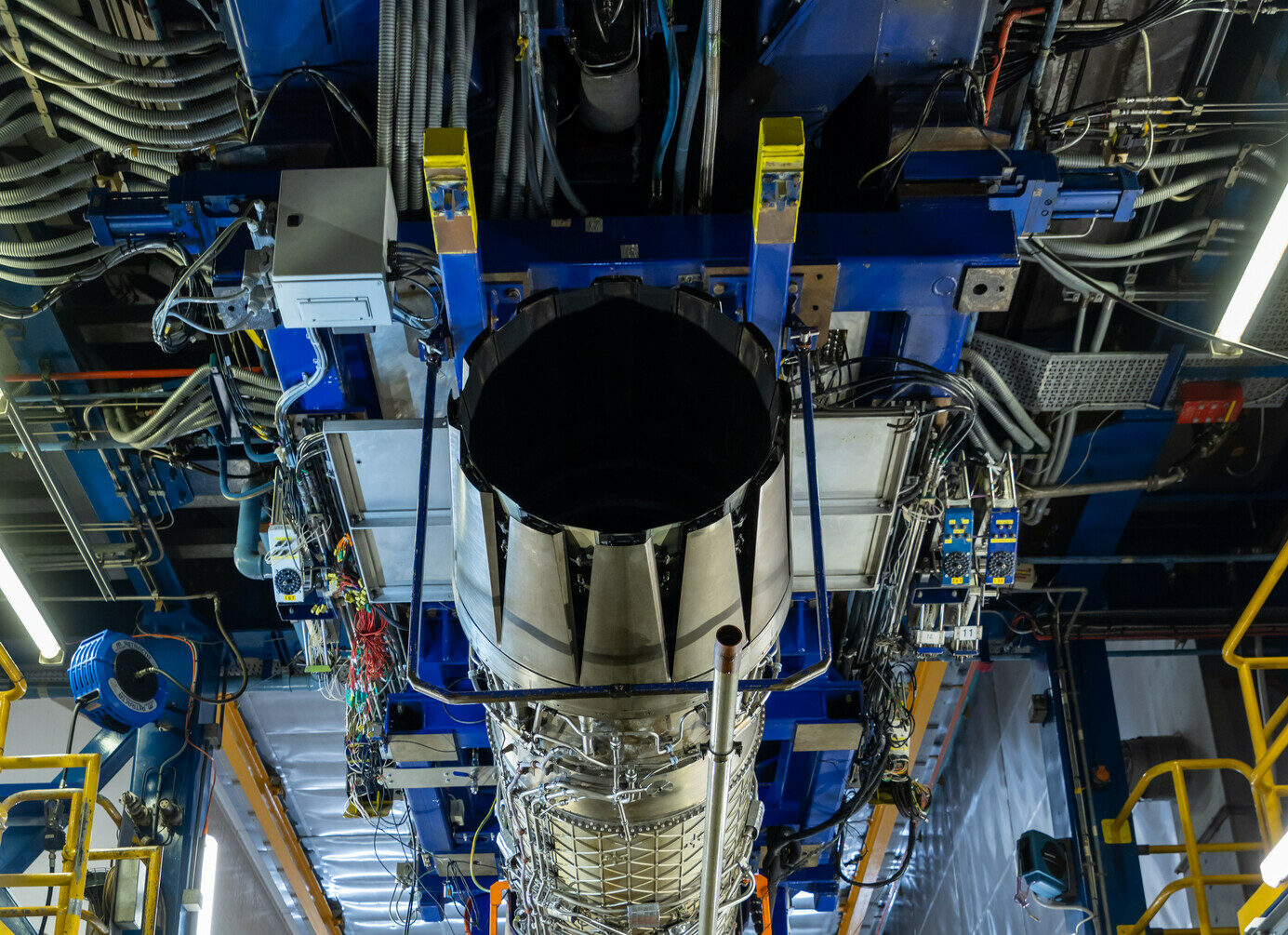

Meanwhile, engineers at Rolls-Royce’s site in Filton, Bristol, have also been carrying out aerodynamic engine testing, “harnessing new advanced manufacturing processes to produce an engine duct which is uniquely shaped to slow the air from supersonic to subsonic speeds at the engine face”, the BAE press release noted. “The intake has fewer moving parts than a traditional fighter jet design, enhancing the aircraft’s stealthy design.”

“The aerodynamic testing has been invaluable in several ways,” Conrad Banks, chief engineer of Rolls-Royce’s future defence programmes, was quoted as saying by BAE. “Not only has it validated complex digital techniques and models, but it has fostered highly collaborative working practices between the BAE Systems and Rolls-Royce teams. We have been delighted with the results and now move forward with confidence that together we can deliver on the next stage of the Flying Demonstrator development.”

BAE Systems also noted that its engineers have been working with UK crew escape specialist Martin-Baker on ejection seat trials using a rocket-propelled sled travelling at speeds of more than 500 mph. Reflecting the fact that new ejection seats are aircraft systems that are infrequently developed, BAE noted that “Experienced engineers have worked alongside junior team members to pass on vital skills that can be taken forward into future developments of Tempest.”

Alongside Martin Baker and BAE Systems, the team behind the Tempest’s crew escape system also includes from GKN (canopy design), Hamble Aerostructures (fitment of detonator cords), and rig manufacturer EDM Ltd, as well as specialists from the RAF’s Rapid Capabilities Office and scientists from the UK MoD.

Team Tempest partners BAE Systems, Rolls-Royce, Leonardo UK, MBDA and the UK MoD are collaborating with a range of British small and medium-sized enterprises (SMEs) to develop the technologies needed to deliver the Tempest programme. The Flying Technology Demonstrator was first announced by the UK government in July 2022, when the MoD said it would fly within five years, setting a pacy schedule for the project.

Neil Strang, BAE Systems’ programme director for Tempest, was quoted by the company as saying, “It’s now 40 years since our people led the demonstrator aircraft programme which gave birth to Typhoon and the work we’re doing today is another once-in-a-generation opportunity to write the next chapter in aviation history. Right across the Tempest programme we’re using digital techniques and innovative design and engineering methods to ensure we can deliver Tempest in service by 2035.

“We already have 1,000 people involved in this programme across UK industry and the supply chain, with young apprentices and graduates working alongside some of our most experienced engineers,” Strang added. “This work will continue to act as a beacon, attracting the very best talent and experience to pass on to future generations of engineers needed for the UK to remain an industry leader in defence and aerospace capability.”

Peter Felstead