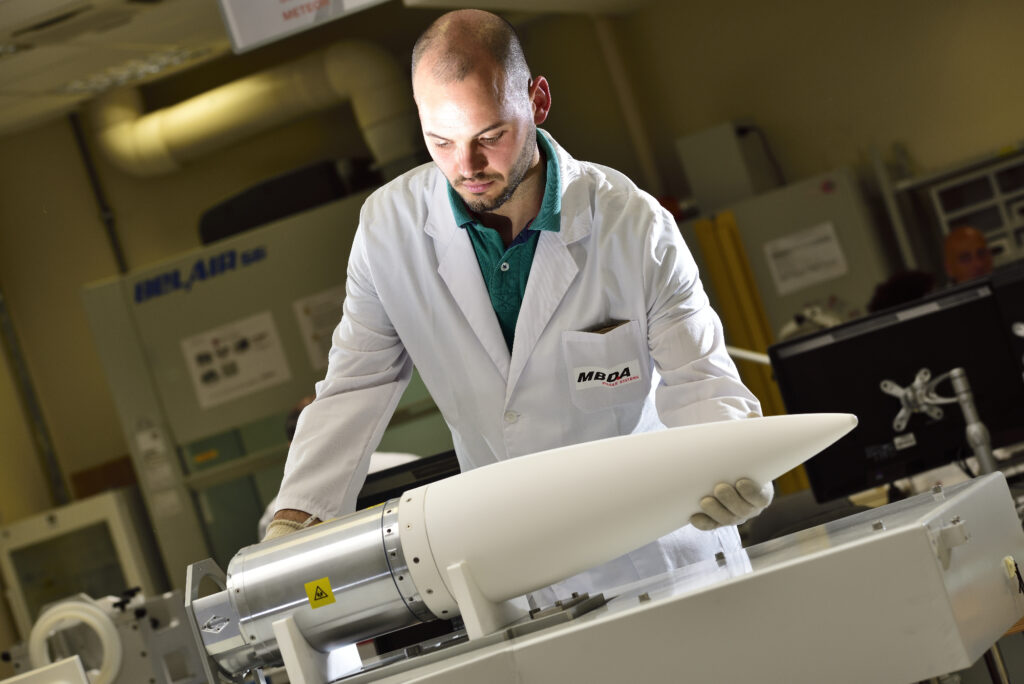

MBDA’s site in Fusaro, on the outskirts of Naples, looks set to get busier in the coming years with potential work on the Future Cruise/Anti-Ship Weapon (FC/ASW) programme and the implementation of new technologies and techniques for the production of missile radomes.

The FC/ASW programme was originally launched in 2017 as an Anglo-French project under MBDA, but a Letter of Intent signed on 20 June 2023 at the Paris Air Show saw Italy set on a path to joining the programme.

Briefing journalists at Fusaro on 12 July 2023, Giacomo Sabino, Research & Technologies Director for MBDA Italia, said he hoped that the company would “enlarge the co-operation” with the French and UK arms of MBDA under the FC/ASW programme.

MBDA is currently pursuing two FC/ASW concepts: a stealthy subsonic cruise missile and a supersonic missile that uses its high speed as a mode of defeat. The capability that emerges from the programme is intended to replace the UK and France’s Storm Shadow/SCALP air-launched cruise missiles as well as their respective Harpoon and Exocet anti-ship missiles. For the Italian military FC/ASW would replace the air force’s Storm Shadows and well as providing a deep strike capability for future Italian destroyers and submarines.

Further to the prospect of FC/ASW work, the announcement on 18 July 2023 that the Italo-French Eurosam consortium (comprising MBDA France, MBDA Italia and Thales) is to produce SAMP/T NG new-generation ground-based air defence systems for the Italian Air Force should also bring more work to Fusaro.

Meanwhile, the Fusaro facility’s position as a key European site for missile radome production could be further strengthened by new production techniques that could produce radomes able to withstand the intense heat generated by supersonic and especially hypersonic flight. While most radomes made at Fusaro are produced using a silica-based liquid suspension that is cast, sintered and milled, a new process is being refined there that uses a ceramic powder, which is placed under high pressure to produce the radome. Currently being patented under the name ‘Nimas’, the new material offers “outstanding” performance, according to Sabino, while costing much the same as the normal silica-based process.

The Fusaro site is also working with ceramic matrix composites to produce radomes, which according to a company spokesman offer more flexibility regarding the shape of a radome and also look promising with regard to hypersonic applications.

Additionally, additive manufacturing is being used at Fusaro to produce certain components and, while current research at the site is just at the initial stages of ceramic additive manufacturing, MBDA Italia personnel working on the technology said they could envision radomes being made additively in “a few years”.

Originally founded in 1921 as a torpedo factory, by 2001 (when MBDA came into being) the Fusaro site was mainly just a production site for the Aspide air-to-air and surface-to-air missile. Now, however, the facility’s activities include research, design and development as well as production related to a whole range of missile system components across a large swathe of the larger MBDA’s missile product range.

As a centre of excellence for both radome and radio-frequency (RF) seeker production, the Fusaro site has produced more than 10,000 radomes and thousands of seekers, Sabino said. The site also produces high-precision RF components and electronic boards as well as conducting integration and testing activities in relation to RF seekers and fuzing; datalinks; battle management, command, control, communications, computers and intelligence (BMC4I) modules/tactical operations centres; and launchers.

As well as activities in test equipment design and integration, the Fusaro site is also conducting work on active electronically scanned-array (AESA) technology and features an anechoic test range facility that can accommodate the testing of high-power AESA and other arrays.

Fusaro’s successes in research and development are substantially assisted by the ties that the site has to universities and research centres, which cover not only Italian academic and research facilities but also ones further afield such as the Georgia Insitute of Technology in Atlanta (Georgia Tech).

Peter Felstead