The US Air Force (USAF) is developing the LGM-35A Sentinel ICBM (formerly known as Ground-Based Strategic Deterrent) to replace its Minuteman III arsenal and retain a viable ground-based nuclear deterrent into the mid and late 21st century.

Credit: Northrop Grumman

The US armed forces have maintained a nuclear triad – consisting of land-, sea- and air-launched weapons, since the 1960s. In recent years some politicians and strategists have advocated eliminating the land-based component. These critics argue that silo-based Inter-Continental Ballistic Missiles (ICBM) are too vulnerable to pre-emptive strikes, and too predictable in their flight path when compared to strategic missile submarines or strategic bombers. However, the Obama Administration’s 2010 Nuclear Posture Review (NPR) reaffirmed the value of the triad concept to ensure a survivable nuclear strike capability and to hedge against adversaries developing defences against any individual strategic weapon system. Subsequent administrations have agreed regarding the need to retain a three-legged nuclear deterrent. The Biden administration’s 2022 NPR concluded that reducing or eliminating the ICBM arsenal would increase risk.

The current US land-based nuclear force consists of 400 deployed Minuteman III ICBMs. Each missile carries a single nuclear warhead. The weapons are operated by the USAF and are dispersed across three bases in the western United States. The Minuteman III was introduced in 1970 and is approaching the end of its service life. Several upgrade programs have extended the system’s viability through 2030, but a replacement is due soon.

GBSD Programme

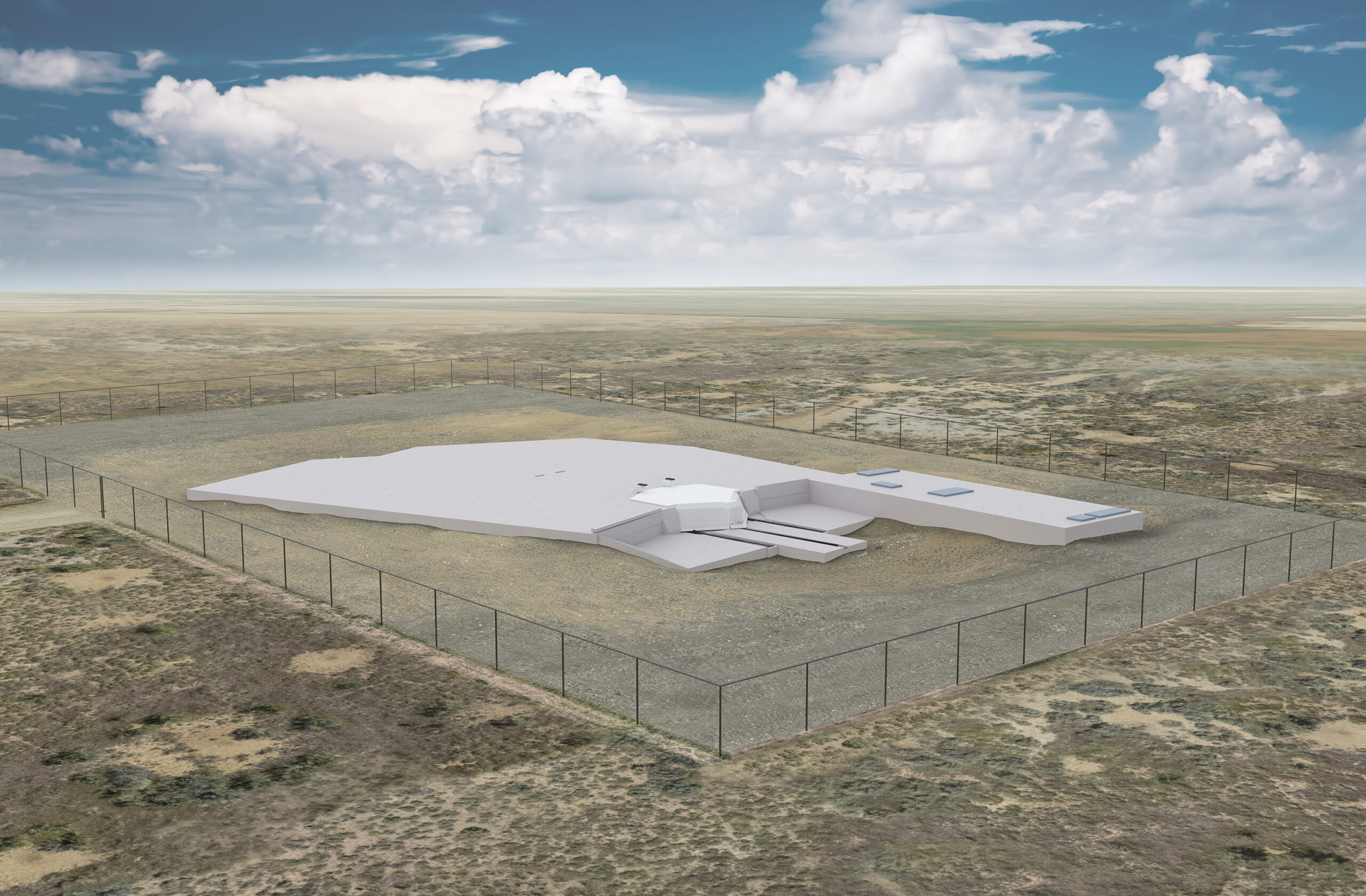

The Ground Based Strategic Deterrent (GBSD) programme (now more commonly known as ‘Sentinel’) will replace the entire Minuteman III inventory with a new missile design, as well as updating or replacing the existing launch silos and ground infrastructure, including the ground launch control facilities. The new missile system was officially designated the LGM-35A Sentinel in April 2022. The designator breaks down into “L” for silo-Launched, “G” for surface (or Ground) attack, and “M” for Missile.

Credit: Northrop Grumman

The USD 96 Bn GBSD program was initiated in 2016 with a Request for Proposals issued by the Air Force Nuclear Weapons Center. Boeing and Northrop Grumman entered bids, and both received three-year preliminary design/technology maturation and risk reduction contracts in 2017. However, Boeing withdrew from the competition in 2019.

The contract for the GBSD’s engineering and manufacturing development (EMD) phase was awarded to Northrop Grumman in September 2020, following a successful Preliminary Design Review (PDR) in April of that year. The firm opened a USD 1.4 Bn facility in Colorado Springs to pursue this and other strategic development programs. The prime contractor is working with approximately a dozen partners including: Aerojet Rocketdyne (solid rocket motor, stage 3 and post-boost propulsion system); Bechtel Corporation (launch system infrastructure); Collins Aerospace (command and control and training systems); General Dynamics (command and control systems, digital engineering environment, aerospace vehicle equipment); Honeywell (guidance and control instruments, booster control); and Textron Systems (reentry system).

Credit: Northrop Grumman

LGM-35A Sentinel

The LGM-35A will feature a modular design and open architecture that will simplify insertion of new technology (both hardware and software) over its service life, ensuring that the weapon system can adapt to changing threat environments as well as incorporate performance enhancing innovations. Maintenance is also expected to be streamlined. Another benefit of the open architecture approach is that the government will be able to control the intellectual property of the system, including source codes. This will enable to Air Force to bring additional vendors into the production and maintenance cycle, rather than tying the service to a single firm. Such flexibility is considered a powerful tool to control cost, while enabling the military to access the best technologies or services available at any point in time.

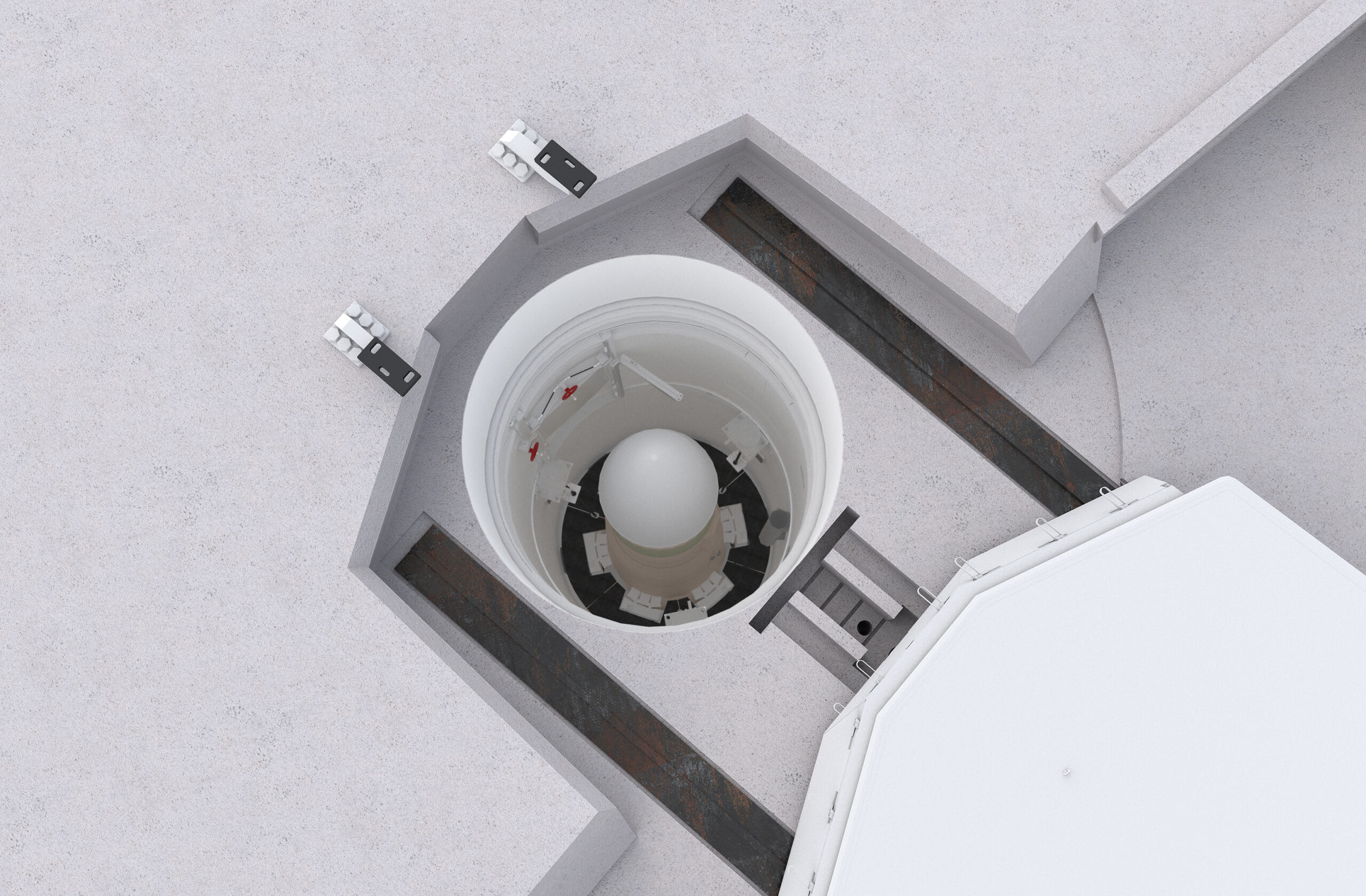

Like the Minuteman III, Sentinel will be a silo-based weapon system consisting of a three-stage booster rocket topped by a shrouded reentry vehicle carrying the nuclear payload. The first two stages of the booster rocket will be built by Northrop Grumman. The third stage is being supplied by Aerojet Rocketdyne.

In contrast to the Minuteman III, which uses steel casings to house the missile propellant, the LGM-35A booster segments will be built from much lighter composite materials while maintaining or improving thrust capacity. This improved thrust-to-weight ratio will increase the missile’s throw weight (the payload weight which can be delivered at any given range) or payload weight capacity. The improved throw weight creates several options regarding future payload configurations or mission profiles. Among other benefits, it would permit the missile to carry countermeasures to overcome missile defence measures which adversaries may introduce in the future; this would likely include electronic countermeasures to overcome enemy electronic warfare and cyberwarfare capabilities developed to interfere with targeting.

Warhead

A new warhead designated the W87-1 is being developed for the GBSD program by the US Energy Department’s National Nuclear Security Administration (NNSA). It is based on the 300 kiloton-yield W87-0 warhead developed in the 1980s and retrofitted onto Minuteman III missiles beginning in 2007. The precise yield of the W87-1 has not been revealed, but the basic W87 design is capable of being upgraded to 475 kilotons.

The new warhead design passed the PDR in 2020. The engineering development phase for the W87-1 commenced in 2022. It is expected to enter production in 2030. One challenge to this goal is the fact that the United States ceased manufacturing plutonium pits in 1989. These hollow spheres form the weapon’s radioactive core; when compressed upon initial detonation they achieve critical mass, unleashing the destructive nuclear chain reaction.

Plutonium pits deteriorate over time, and must ultimately be replaced. To ensure sufficient supply for production of the W87-1 and other developmental nuclear warheads, the NNSA is building a new uranium processing facility. The Energy Department plans to produce 80 new plutonium pits per year by 2030. However, according to Congressman Seth Moulton who sits on the House Armed Services Committee, the new NNSA facility is currently “up to two years” behind schedule. Plutonium pit production at the rate required by the Department of Defense (DoD) will not be achieved “until the mid- to late-2030s,” Moulton said during a 28 March 2023 hearing, casting doubt on the ability to field the W87-1 on schedule.

Credit: Northrop Grumman

Reentry Vehicle

The W87-1 will be mounted on the Mk21A reentry vehicle currently being developed by Lockheed Martin under a non-competitive 2019 award. The period of performance for the Technology and Risk Reduction contract runs from 2020 through 2024. The Mk21A passed the preliminary design review in March 2021. However, the first of two scheduled flight tests of the new reentry vehicle failed in July 2022 when the Minotaur II booster rocket being used exploded only 11 seconds after launch. The next prototype test launch is scheduled for later in 2023, to be followed by award of the Engineering Manufacturing and Development (EMD) contract and the Production and Deployment (P&D) contract. The Air Force Nuclear Weapons Center procurement office has stated the period of performance for both contracts is expected to run through 2036. The Mk21A is expected to enter service in 2030.

The Pentagon is simultaneously planning to develop a more advanced reentry vehicle designated the Next Generation Reentry Vehicle (NGRV). The NRGV would be capable of accommodating both current and future warheads. In March 2023 the Air Force requested USD 15.5 M in funding to begin research in FY 2024; a corresponding Request for Information (RfI) to industry was published in April 2023. USAF hopes to award a development contract in FY 2026. Details of the NGRV remain classified, although the Pentagon has said the new RV must display enhanced survivability, accuracy and lethality.

The 2024 budget documents also state that “future NGRV solutions… will include acquisition of complementary countermeasures.” While the military declined to comment, many defence analysts speculate that the NGRV could be designed with an option to carry more than one warhead should the strategic environment and the national defence policy require it. Alternate theories include development of a new, independently manoeuvrable single warhead which could display greater accuracy than current warheads.

Progress to Date

Supply chain and workforce issues at Northrop Grumman and several subcontractors have forced delays in the original development timeline. This includes moving up the original target date for first deployment of the new missile from FY 2029 to FY 2030. At a 28 March 2023 hearing before the House Armed Services Committee Deborah Rosenblum, Assistant Secretary of Defense for Nuclear, Chemical and Biological Defense Programs, testified that the DoD and USAF were jointly working to accelerate development in order to regain the original timeline, although the outcome of these efforts – which include giving the LGM-35A programme preference with regard to supply deliveries – remains uncertain.

Credit: Northrop Grumman

Despite the supply chain handicaps, Northrop Grumman and its subcontractors have managed to manufacture physical prototypes of major components. This early assembly reduces programme risk by validating production techniques and ensuring that physical assembly matches the digital modelling.

A major focus in this regard is placed on the booster motors which constitute the major element of the actual missile. Assembling the propulsion system is a multi-stage process. The solid propellent engines are cast by pouring rocket fuel into motor casings in a highly complex procedure. Several overlapping layers of protective material are then applied over each booster stage. The central casing of each motor requires insulation as protection against the extreme heat of burning fuel. A composite material is then applied over the insulation; this so-called ‘case wind’ forms the outer shell of the motors. A final protective material is applied over the case wind. For this last stage Northrop Grumman has devised a new, more efficient application procedure which reduces processing time by two-thirds.

Credit: Northrop Grumman

Engine production for the three stages of the booster rocket was initiated in 2022. Inert stage one and stage two rocket motors were cast by Northrop Grumman in Summer 2022 to demonstrate motor design maturity and validate manufacturing processes, advanced tooling, and facilities. Fully functional motors were subsequently manufactured late in 2022 for use in ground testing.

Early Testing

The first full-scale static fire test of the stage one solid rocket motor took place on 2 March 2023 at the Northrop Grumman test facility in Promontory, Utah. This was the first in a series of tests of the weapon system’s hardware under real-world conditions, said Major General John Newberry, Air Force Nuclear Weapons Center commander and Air Force program executive officer for strategic systems. “This test is just one part of our comprehensive ground and flight test program designed to help us shake down the design as we approach its critical design review. By testing early, we reduce risk to the overall weapon system schedule,” Newberry said.

The engine firing was preceded by a series of wind tunnel tests using scaled models of the LGM-35A. According to a 16 February 2023 Northrop Grumman press release, the experiments were performed over the course of a year at various government and corporate facilities, and consisted of seven comprehensive test campaigns. Each campaign was designed with a unique set of requirements to measure how the missile would respond to various atmospheric, load and speed conditions. The full operational gamut was simulated, from launching the missile, to stage separation and various flight manoeuvres at subsonic and hypersonic speeds. The release stated that the physical test campaign validated the program’s digital modelling and simulations, and proved the design maturity of the missile. According to the release, “the team is now updating models to enable full-scale predictive environments for the development of Sentinel flight hardware” as the engineering and design maturation efforts continue prior to Critical Design Review.

Credit: Northrop Grumman

Fielding

Both the Pentagon and industry express confidence regarding successful transition through the remaining major milestones and testing events. The Critical Design Review (CDR) is currently scheduled for the fourth quarter of FY 2023. According to statements by the Air Force and Northrop Grumman, the first test launch of the LGM-35A all-up-round (consisting of the booster missile with mounted reentry vehicle) is expected during the third quarter of FY 2024. It will be conducted at Vandenberg Space Force Base in California. If all goes well, the Milestone C decision to proceed with procurement is scheduled for the third quarter of FY 2026. This will lead to Low-Rate Initial Production (LRIP).

The Pentagon plans to declare LGM-35A Initial Operational Capability (IOC) in 2030 with nine missiles on alert status. The earliest units might be armed with older Mk21 reentry vehicles and W87-0 warheads pending availability of the new Mk21A and W87-1 variants.

Full Rate Production (FRP) is anticipated for 2030. The Pentagon plans to acquire 642 units of the new missile. Of these, 400 will be deployed, with the remainder to serve for testing and as a reserve. Initial LGM-35As will serve alongside legacy Minuteman III missiles in order to retain a steady arsenal of 400 ICBMs. The acquisition program is to complete in 2036, when 400 units are expected to be deployed, replacing the Minuteman III at a one-for-one basis. As the US still maintains 450 operational missile silos, the future deployed ICBM force could hypothetically be expanded to address changes to the strategic environment. The LGM-35A is expected to remain operational past 2075.

Sidney E. Dean