Background

Through-life capability management (TCLM) is a comprehensive approach to ensure the longevity, performance, and cost-effectiveness of defence materiel that often drives the adoption and adaptation of some surprising innovations.

Predating the birth of today’s tank commanders, the UK Ministry of Defence pioneered a form of smart acquisition that considered many price and cost factors, from design and specifications to maintenance regimens and material durability. This included examining other factors that have consequential cost effects based on choices made in this process. Becoming known as TLCM, it remains a remarkable way to manage materiel, maintain capabilities while reducing – if not holding down – total costs of ownership (TCO).

The lay of the land

Armoured fighting vehicles (AFVs) have a significant TLCM challenge based on several factors that are related to TCO and, simply, choices made at their design stage. AFVs – particularly those equipped with steel tracks – historically have maintenance and operational sustainability challenges. While steel tracks are durable, and seem to be cost-effective at first glance, they are encumbered with several expensive drawbacks:

- Many other associated parts that wear out quickly;

- Lack of spare part logistical reliability;

- Labour-intensive maintenance;

- Extended periods where AFVs are out of service;

- Damage to on-camp roads and civilian streets;

- Extreme vibration, causing adverse effects on an AFV’s crew health, ordnance, and electronic systems;

- Increased vehicle weight that slows its movement and increases fuel consumption.

All these factors represent direct and indirect costs that a military must account for and shoulder, significantly increasing TCO for an AFV fleet to maintain its battle readiness.

Innovation option

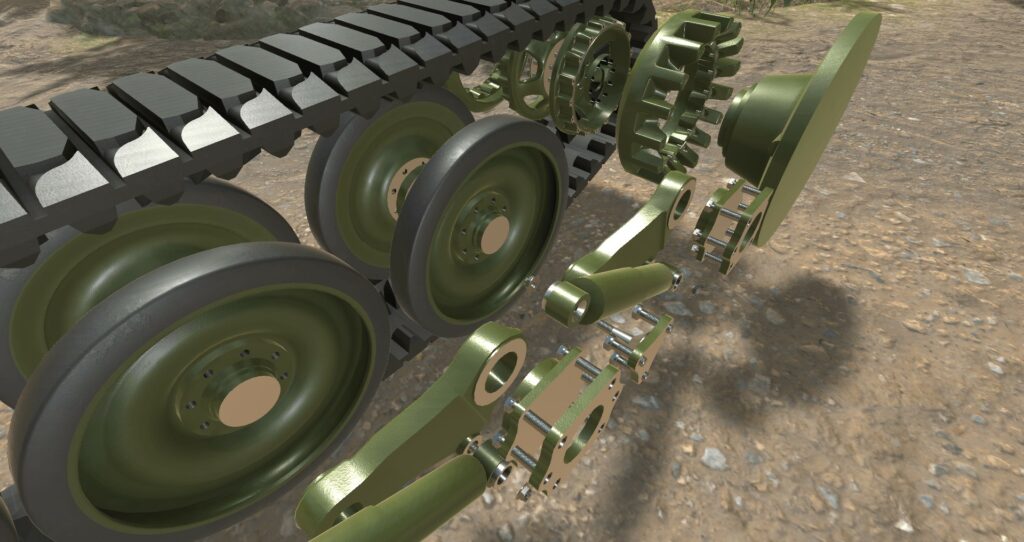

Surveying AFVs as an ecosystem from the ground upward, using TLCM principles, it was possible to determine that steel tracks were at the foundation of their overall TCO problems. This created opportunities for the few companies with a specific expertise with rubber and other man-made materials. For example, Soucy developed composite rubber tracks (CRTs) as a single, simple innovation that remedies all of the steel tread ills.

Soucy introduced an innovative material design that fulfils the critical conditions of TLCM by utilising fewer components, requiring minimal maintenance and reducing costs over time.

What works is …

As ‘capability management’ is at the heart of TLCM it bears examining how the introduction and adoptions of CRTs facilitate this aspect of TLCM before reviewing obvious benefits.

- Task redundancy

The reduced maintenance requirements of CRTs have a direct impact on the allocation of human resources: less time on maintenance allows personnel to focus on other mission critical duties. This is crucial in autonomous or semi-autonomous platform operations whereby the small crew’s time is limited, so tasks require efficient execution.

- Data corroboration

Numerous user trials and data from military exercises corroborated Soucy’s own findings concerning substantial reductions in vibration, weight, and fuel consumption. Empirical evidence was essential in establishing the credibility and reliability of CRTs in diverse operational environments, proving their efficacy is not solely based on manufacturer claims.

- Fielding advantages

CRT efficiencies include strategic logistics. A reduction in spare parts requirements converts to decreased reliance on easily disrupted intermodal transport for deliveries. This streamlines and secures logistical processes, ensuring a smoother flow of material and equipment to and from an operational theatre.

The adoption/adaptation of CRTs brings numerable key benefits to TLCM planning and acquisition:

- Reduced noise and vibration

Decreasing crew and component fatigue is an exceptional CRT benefit with a remarkable 70% reduction in vibration, providing more than a smoother and quieter ride. As well as major implications for the longevity of sensitive components, CRTs reduce an AFV’s noise and radar signature: crucial for success in modern warfare.

- Enhanced durability and fuel economy

The CRT system’s greater durability means AFVs have extended operational periods before requiring maintenance. The inherent lighter weight of CRTs contributes to improved fuel efficiency, optimising operational costs and ensuring sustained missions.

- Operational flexibility

The lightweight construction of CRTs also plays a pivotal role in operational flexibility, most significantly in urban operations, whereby manoeuvrability is paramount to achieving success. For example, improved braking and turning capabilities offered by CRTs provide an AFV with a decisive edge in navigating difficult terrain and thus increase tactical effectiveness.

- Logistical costs

Fundamentally, CRTs emerge as a cost-effective solution because of reduced parts and maintenance requirements. The saved financial resources are able to reach other critical areas that enhance overall force availability and capability. One could additionally argue that, with reduced logistical activities, there is a reduced carbon emissions footprint to be realised.

- Increased resilience

Because of their material strength and composition, CRTs mitigate the effects of mine and improvised explosive device (IED) strikes. This is vital, as in past operations there has been a proliferation of sophisticated mines and IEDs targeting armoured vehicles.

Altering views

Despite the advantage of CRTs, doctrinal adoption necessitates a mindset change; it is still classified as a ‘Level 2’ task. Benefits far outweigh challenges associated with this transition.

The ability to last circa 5000 km without maintenance is a noteworthy and unique benefit of CRTs. This characteristic facilitates repair and operational planning predictability that is essential for combat effectiveness assessment and accurate supply planning, while also aiding in devising comprehensive strategies for mission success.

Acquire & sustain

The Australian Land 400 Phase 3 infantry fighting vehicle (IFV) acquisition was structured to deliver a winning solution based on an extensive testing and evaluation regimen, with the selection and fielding process based on a firm timetable. From four contenders Australia downselected two competitors for the final phase of the selection process in September 2019: Hanwha Defense Australia with the AS21 Redback and Rheinmetall Defence Australia with the KF41 Lynx. Final trials and evaluations during the following three years encompassed the Australian Defence Force’s operational environments as part of a risk mitigation activity.

By July 2023 the Redback had won the programme, with the acquisition contract signed in December 2023. One major ‘plus’ for the Redback was that it featured CRTs, while the competing KF41 was equipped with conventional steel tracks.

The capabilities of CRTs for armoured vehicles have advanced substantially in recent years, moving up the AFV scale from M113-class vehicles, to CV90 IFVs to the more-than-45-tonne weight of the Redback, with further developments to accommodate even heavier AFVs in prospect.

Evaluating the choice between a CRT solution for an AFV versus conventional steel tracks through a TLCM lens indicates that CRTs have distinct advantages over the service life of a vehicle. These advantages are both operational and economical, based on real world data.

What next?

The AFV sector continues to experience paradigm shifts. The introduction of CRTs, such as those from Soucy, is ground-breaking technology, literally and figuratively, offering many benefits across manned and unmanned ground platforms, the least of which is benefitting from TLCM principles.

Simply adopting CRTs as a technical material innovation is a strategic TLCM enabler for AFV platforms. As evidenced, the manifold cost benefits of CRTs are surpassed by them being a catalyst for improving military mobility, longevity, durability, and capability.

As armed forces continue to evolve out of necessity, it is necessary to embrace new technologies with more than one benefit. In the AFV case, CRTs become imperative for ensuring armoured platforms are as formidable on the battlefield as they are financially and logistically sustainable throughout their (now extended) operational lives.