Submersible vessel programmes

Sidney E. Dean

Submersible vessels capable of both surface and underwater operations provide flexible options for Special Operations Forces. They are considerably smaller than conventional attack submarines, and serve a variety of mostly specialised mission types.

Special Operations Forces (SOFs) are the primary users of manned submersibles, which have popularly been referred to as miniature/midget submarines or mini-subs. They are specifically designed for the covert transport of SOFs and their equipment in high-threat or access-denied areas. They are also suitable for direct action and intelligence, surveillance and reconnaissance (ISR) missions. This article examines some of the submersibles in service or under development, focusing largely on current American, British and French designs.

United States: SEAL Delivery Vehicle (SDV)

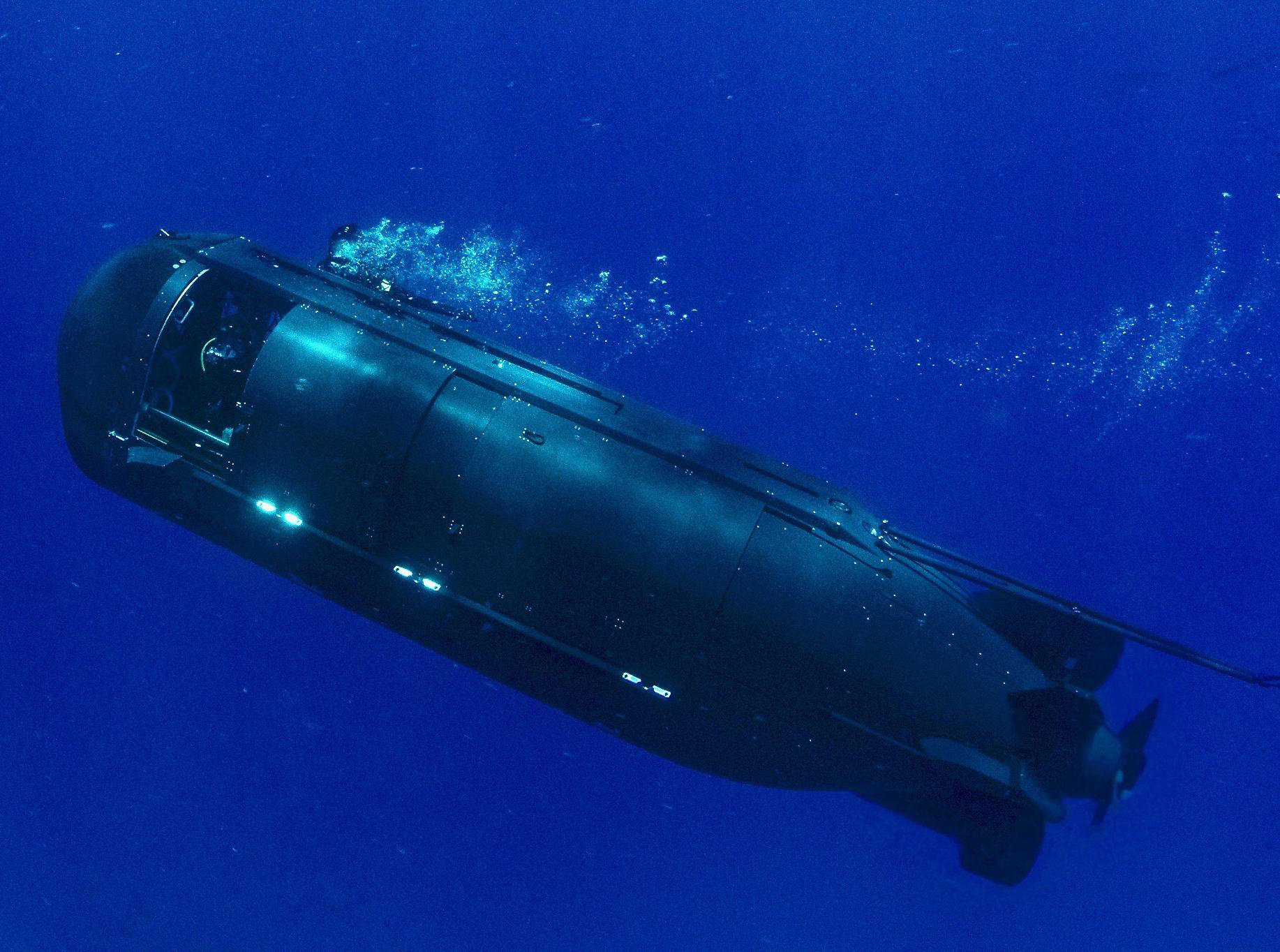

The US Naval Special Warfare Command (NAVSEPCWARCOM) is among the world’s leading operators of mini-subs. Since the 1980s the US Navy’s Sea Air and Land Teams (SEALs) have relied on the SEAL Delivery Vehicle (SDV) Mk 8 for underwater transportation to their mission objectives; the only other unit to utilise this particular system is the British Royal Navy’s Special Boat Service (SBS). The SDV is carried in a dry deck shelter (DDS) mounted atop specially configured attack submarines or ballistic missile submarines (the vehicle can also be launched by surface vessels, but this conflicts with the goal of covert underwater delivery). The 15 tonne mini-sub accommodates a total of six operators including the two-person crew. Reported performance parameters include a 4 knot cruising speed, 18 NM range fully loaded, and 12 hour endurance, with a dive depth of 6 metres. Notably, the SDV is a ‘wet’ submersible; the divers’ rebreathers are attached to the vehicle’s life support system while en route, but they are exposed to the water and endure fatigue before even reaching their destination.

Credit: US Navy

The Mk 8’s replacement, designated the Shallow Water Combat Submersible or SDV Mk 11, entered service in 2020 and achieved initial operational capability (IOC) in 2022. It was designed by Teledyne Brown Engineering under a 2011 contract with the US Special Operations Command (SOCOM), and produced through to 2024 under two 2019 and 2021 follow-on contracts. The aluminium-hulled Mk 11 is 30 cm longer, 15 cm higher and 1,800 kg heavier than the Mk 8, according to SOCOM briefing documents. Improvements over the Mk 8 include upgraded computers and networking (including the ability to communicate with external manned and unmanned platforms), improved software and user interface, higher accuracy navigation, and addition of bow thrusters for enhanced manoeuvrability. Additions include a sensor mast with an electro-optical periscope, sonar detectors for obstacle and mine avoidance, and a sonar-assisted automatic docking capability. Crew members are connected via both wireless and wired communications interface. While some performance parameters are classified, the Mk 11 is reported to have a range of approximately 36 NM at a cruising speed of 4 knots. Like the Mk 8, the SDV Mk 11 is also being acquired by the British SBS.

United States: Dry Combat Submersible (DCS)

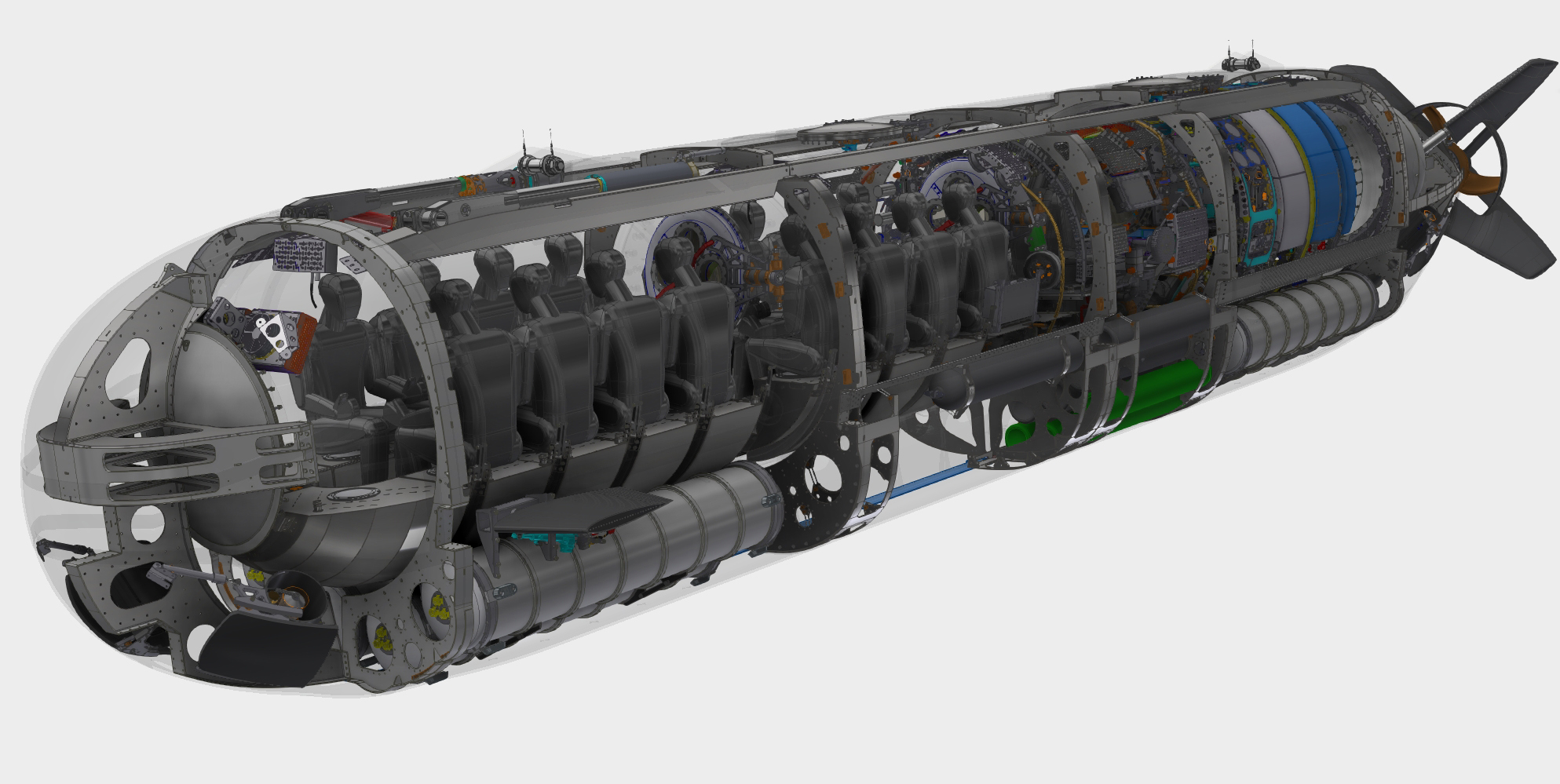

SOCOM has also introduced a second new manned underwater vessel designated the Dry Combat Submersible or DCS. As the name implies, the vessel is fully enclosed and pressurised, permitting the crew and passengers to remain dry, warm and rested during transit. They can wait to don their diving gear until arrival at the egress point, which again contributes to comfort and reduces fatigue during travel. These attributes are expected to have a direct and major impact on mission safety and success by delivering the commandos in fit condition, both physically and mentally.

While many aspects of the DCS remain classified, the known performance parameters offer significant improvement over the SDV Mk 11. These include a reported range of over 60 NM, with a cruising speed of 5 knots and a classified top speed. The submersible is rated for 100 metres depth. Mission endurance exceeds 24 hours. The DCS’ capacity is almost double that of the Mk 11, with a two person crew (pilot and navigator) and room for an additional eight fully-equipped commandos or one metric tonne of cargo.

Two variants designated as DCS Block 1 and Block 2 are planned. The first Block 1 unit was delivered to NAVSEPCWARCOM in 2020 for developmental testing and operational testing. It subsequently reached IOC in June 2023 and full operational capability (FOC) in 2024 according to US Navy Cmdr Jonathan Connelly, program executive officer for the command’s maritime undersea systems. Prime contractor Lockheed Martin RMS developed and built the DCS Block 1 jointly with major subcontractors Submergence Group LLC (Texas) and Msubs Ltd (UK). The DCS Block 1 is based on an Msubs design, the S351 Nemesis, although the design has been modified to meet NAVSPECWARCOM requirements. Construction of the submersibles takes place in the UK, followed by pressure hull inspections by Germanischer Lloyd (now part of DNV GL) in Cuxhaven, Germany. Subsequently the pressure hulls are sent to the United States for final system integration by Lockheed Martin.

Many details of both the DCS’ and the Msubs’ designs remain classified. External features of the DCS Block 1 and the Nemesis appear very similar, including a length of 12 metres length, a height of 2.5 metres, and a displacement of around 30 tonnes. The pressure hull is divided into three watertight sections: the cockpit is located aft, while the passenger/payload compartment is forward. Above water, personnel access the vessel through a retractable accordion tower located over two hatches in the midships dorsal section. The lock-in/lock-out chamber for entering and exiting the submersible underwater is midships in the lower hull section. The propulsion and steering systems include a shrouded screw with curved blades to avoid cavitation, X-form rudder control surfaces, retractable thrusters forward and aft for fine positioning and transit of tight spaces, and hydroplanes forward. Electricity for propulsion and internal systems is generated via lithium-ion fault tolerant (LiFT) batteries developed by General Atomics Electromagnetic Systems (GA-EMS). According to GA-EMS, LiFT battery technology is designed to provide increased endurance and longer battery lifecycles, while improving safety over conventional lithium-ion battery designs; the modular design reduces the likelihood of uncontrolled and catastrophic cascading lithium-ion cell failure. In the long run SOCOM would like to acquire even higher performance battery systems. To this end it has been investigating the potential of aluminium-seawater (Al-H2O) batteries for the DCS and other underwater vessels. According to L3Harris, the high energy density technology can provide between twice and 10 times the endurance of other battery systems. If eventually applied to the DCS, it could extend the submersible’s mission range to several hundred NMs.

Some key systems have been customised to meet SOCOM requirements. These included the bow-mounted terrain-following/terrain-avoidance sonar for shallow-water navigation, and the radio frequencies countermeasures sensor and library (for detecting, classifying and evading hostile radar). Additional optical and electronic sensors and communications links are mounted on two retractable masts.

To date the US military has received three DCS Block 1 submersibles, with no additional units on order at this time. NAVSPECWARCOM’s major remaining concern with the Block 1 is the fact that it is too large to fit inside a Dry Deck Shelter, and therefore can only be launched by surface vessels, either by crane or from a well-deck. Given the submersible’s mission range of around 60 NM, the risk that the vessel’s launch will be observed is high. The DCS Block 2 configuration, now designated the Submarine Launch Dry Submersible, will be required to be compatible with submarine carriage to ensure stealth. Few details of this variant, which is in development, have been made public. In 2023 SOCOM Acquisition Executive James Smith told reporters he was pleased with the rate of progress. “We’re reliant on the Navy for the success of that program and really happy with how the relationship is progressing,” Smith said, adding that the US Navy would determine when the new submersible is ready for operational certification.

Credit: Lockheed Martin

United Kingdom: S401

Msubs has developed an array of manned submersibles; some smaller and some larger than the S351. This includes the S401, which for the moment is strictly a concept. The 16 metre long vessel would have a displacement of 40 tonnes, and would likely become the largest currently operational mini-submarine if put into production. A modular configuration permits a trade-off between payload or passenger load on the one hand and battery pods on the other, permitting operators to prioritise either the size of the commando contingent or range and endurance. Maximum capacity would permit carriage of 16 combat divers in addition to the pilot. Msubs envisages a default power system option that uses LiFT batteries but offers optional integration of fuel cells or diesel-electric propulsion to extend range and endurance.

Credit: Msubs

United Kingdom: Carrier Seal and Shadow Seal

The Carrier Seal and Shadow Seal watercraft offered by United Kingdom-based James Fisher Defence (JFD) are optimised for covert transport of combat divers. However, the potential mission profile also includes maritime interdiction, stand-off attack and fire-support, and ISR. Unlike many other submersibles, both are full-fledged multi-domain vessels capable of operating in three modes: surface, semi-submerged and submerged. This permits a high-speed surface approach to the mission zone, requiring transition to underwater operations only when near the target. Deployment options include launching from a surface vessel, deployment and recovery by medium-lift rotary aircraft (sling load), or airdrop onto the ocean surface via tactical transport aircraft. Both are configured as ‘wet’ submersibles.

The Carrier Seal is 10.5 metres long with a displacement of 4.3 tonnes; with only 50 cm draught, it can manoeuvre almost anywhere. It accommodates two pilots and six combat divers. The agile vessel incorporates a 345 hp diesel engine coupled to a waterjet propulsor for above-water transit and semi-submersed mode. Fully submersed it switches to two, 20 kW Lithium-Polymer batteries which power two electric thrusters. Surfaced, the vessel operates as a speedboat at up to 30 knots with a range of 150 NM. In semi-submerged and submerged modes the Carrier Seal slows to 4 knots cruise and 6 knots sprint speed or 3 knots cruise and 5 knots sprint, respectively. Range under water is 15 NM. While demonstrating the Carrier Seal at SOF Week 2024 in Tampa, JDF cited a maximum depth range of 30 metres, although the firm’s published data sheets have previously stated a range of 40 to 50 metres. Both surface and subsurface range can be doubled by carrying an auxiliary fuel pod and/or extra battery packs.

Credit: James Fisher Defence

The Carrier Seal is equipped with several mounts for a variety of weapons, permitting its deployment as a combat boat when needed. To support reconnaissance, surveillance and intelligence missions the vessel can also be equipped with side-scan sonar, remotely operated vehicles and autonomous underwater vehicles.

The firm’s smaller Shadow Seal accommodates a two-person crew and two passengers. JDF first showcased the submersible in 2023 at the SOF Week in Florida and the DSEI exposition in London. The firm defines the 8 metre long, 2,500 kg vessel as a tactical diving vehicle or TDV with a maximum dive depth of 24 metres. Surface performance includes a speed of 5.5 knots with a range of 80 NM, while submerged operation reaches 4.5 knots and a 25 NM range.

In September 2023 a JDF press release confirmed that “the Carrier Seal is in operation with a number of the world’s navies,” without identifying the operators. In 2022 the firm partnered with US-based Blue Tide Marine (BTM) “to provide local demonstration and training services” in hopes of enhancing marketing opportunities in North America.

United Kingdom: Victa

SubSea Craft, another UK-based designer, achieved proof of concept certification for its Victa diver delivery unit (DDU) in July 2023 following extensive sea trials. This paved the way to begin construction of the first production-standard vessel. While the firm hopes to market Victa to the British Special Operations Forces, no acquisition decisions have been reported to date. Following certification, the firm’s CEO Scott Verney stated that the firm would continue to evolve and enhance the design to accommodate client preferences and the evolving operational environment.

The vessel is equipped with a Seatek 725 hp diesel engine powering twin propellers, and a high-capacity lithium-ion battery system powering electric thrusters. Victa achieves a top surface speed of 40 knots and a cruise speed of 30 knots, with a surface range of 250 NM; submersed the vessel achieves 8 knots with a 25 NM range, and a dive limit of 30 metres. The transition between surface and subsurface mode requires two minutes. Fly by wire controls and AI-augmented control and navigation systems reduce pilot workload. SubSea Craft intends to develop remote operation and autonomous operation capability in future iterations of the vessel.

Credit: James Fisher Defence

The 12 metre long vessel seats eight including the two-person crew. The cabin can be reconfigured to accommodate various mission payloads at the expense of a smaller number of personnel. The mono-hull vessel is constructed of carbon fibre with a composite core. The streamlined form of the enclosed cabin reduces the radar cross-section during surface operations.

While the vessel is fully enclosed during surface operations, the hull is flooded when submerged. While this can have a negative impact on crew comfort, the ‘wet’ submersible is associated with several advantages, beginning with greater design simplicity and reduced cost (due in part to the lack of organic life support systems). Operationally, the flooded hull provides greater stability and enhanced manoeuvrability compared with the buoyancy issues which can arise with dry submersibles.

France: SWUV/PSM3G

France’s then ECA Group (now Exail) presented its Special Warfare Underwater Vehicle (SWUV) at the 2014 Euronaval exhibition in Paris. Classified as a SDV, the 8.5 metre long SWUV has a capacity of six, including a two person crew. To date, both Exail and the French Navy have shrouded the system in secrecy, with few structural or capability details being revealed. Performance parameters supposedly include a top speed of 10 knots and a maximum diving depth (depending on source) of between 60 and 100 metres. One of the few official comments was a November 2019 Tweet by then French Naval Chief of Staff, Adm Christophe Prazuck, announcing that he had participated in a dive in the new SDV.

Credit: SubSea Craft

The French armed forces have designated the vessel as the PSM3G or third generation swimmer delivery vehicle. Various media reports agree that it was accepted into service in late 2019, which would be consistent with the timing of Adm Prazuck’s demonstration dive. The PSM3G is being acquired specifically for the navy’s Commando Hubert SOF combat swimmer unit, although there is speculation that it could also be used by the combat swimmers of the national intelligence service, the Direction générale de la sécurité extérieure (DGSE). The PSM3G can be launched by surface craft or be carried by an 11 metre dry deck shelter on a Suffren class submarine. This grants the divers dry access to the SDV via an airlock from the submarine. Mission options include commando transport, shallow water/coastal ISR, and the underwater transportation and placement of explosives.

France: Coryphene and Sphyrene

In August 2023 the French Navy introduced another new SDV, the Alseamar-produced Coryphene. The 6 metre long SDV provides tandem seating for a pilot and a navigator/systems operator. An additional space behind the navigator accommodates either a third person or an optional retractable optronics mast. The Coryphene reaches speeds of 8 knots and a range of 50 NM (at 5 knots cruising speed). A 1 metre, narrow beam facilitates navigation in cluttered or restricted environments.

Alseamar is also developing the Sphyrene SDV, which is currently at the concept-development stage. Intended primarily for the export market, the 8 metre long Sphyrene will accommodate six divers including its crew. Objective performance parameters include a top speed of 9 knots and a range of 70 NM at 8 knots cruising speed. Like the Coryphene, the Sphyrene can be outfitted with a telescopic optronics mast.

Both SDVs can be deployed from ships, specially configured boats, or from submarine-mounted cradles and DDSs. Both operate as ‘wet’ submersibles, with crew and passengers receiving a nitrox via the vehicle’s life-support system. The submersibles can travel open at depths up to 25 metres; with the access hatches closed, the Sphyrene can descend to 50 metres, while the Coryphene can operate as deep as 100 metres. Both SDVs are equipped with integral sonar with a 350 metre range. Additional navigation and manoeuvring systems include INS and Doppler velocity logging (DVL). Satellite communications ensure connectivity with the mothership or shore stations. The cockpit instrumentation features user-friendly human-machine interface configuration to reduce crew stress and enhance manoeuvrability.

Credit: Highland Systems

United Arab Emirates: Kronos

The greatest drawback of submersibles is their lack of speed when operating underwater. Highland Systems, a UAE-based start-up founded by Ukrainian engineers, promises to resolve this issue while also enhancing many other performance parameters. The firm publicly presented its Kronos concept at the NAVDEX 2023 exhibition. Externally the 9 metre long, 7.4 metre wide vessel appears to be inspired by a manta ray or a science fiction movie ‘death glider’. The designers state that its innovative shape and the composite material overlaying the steel hull are optimised for signature reduction, making the Kronos a stealth vehicle. A hybrid propulsion system includes a diesel engine for surface mode and an electric drive for submerged operations. Highland Systems cites a targeted top speed of 43.2 knots surfaced and 27 knots submerged. This is combined with the ability to manoeuvre and turn sharply at full speed, even under water. The vessel is configured for a standard operating depth of 100 metres, with a maximum critical depth of 250 metres. The design accommodates a single pilot plus 10 passengers. Total mission endurance is given as 54 hours, including 36 hours on the surface and 18 hours submerged, with a 36 hour on board air supply as a safety margin. Recharging the battery and the air tanks requires 90 minutes on the surface. In addition to 10 combat divers, the Kronos can also carry up to six light torpedoes or, optionally, an onboard underwater or aerial drone.

Credit: Alseamar

Given the complexity of submersible design, Highland Systems’ concept – as presented – appears extremely ambitious. Should even a portion of the targeted performance criteria eventually be met, Kronos would constitute a major leap forward for underwater Special Operations capabilities, and set new baselines for future systems.

Sidney E. Dean