Whether caused by mechanical failure, accidental damage or the result of enemy action, a disabled submarine at depth is no place any submariner wants to be.

From accidents such as HMS Thetis in 1939, the Kursk in 2000 and many more besides, to wartime episodes involving damage or destruction to submarines of all sides by enemy action, submariners live dangerous lives and most navies have long since recognised the need for effective escape and rescue procedures, techniques, and equipment. Today, submarine rescue has become a highly skilled, technologically impressive arena, led by just a handful of organisations and specialist companies such as Forum Energy Technologies (FET), JFD, and Oceaneering, with unprecedented, technologically advanced skillsets.

Credit: NATO

New procedures, systems, technologies, as well as a greater understanding of the medical aspects of rescuing human beings from great depths are all part and parcel of what goes into current submarine escape and rescue doctrine. In a submerged, disabled submarine (DISSUB) scenario, where every minute counts, escape from the boat and reaching the surface quickly without external assistance is an ideal scenario, if the vessel is at a depth and in a condition that makes self-escape for all crew practical. The likelihood is, however, that some sailors may be injured, making their escape impractical and rescue, therefore, essential. This is where submarine rescue by external specialist teams enters the picture, with the latest submersible rescue vehicles (SRV) employed to remove trapped and injured crew from a DISSUB and returning them safely to the surface.

While escape or rescue are, effectively, the only two acceptable options available to the crew of a submerged DISSUB, this article looks at the rescue side of things, primarily through the procedures and activities employed by the NATO Submarine Rescue System (NSRS), key stakeholders and other submarine rescue specialists.

Credit: NATO

The NSRS

An international collaboration between France, Norway and the UK, the NSRS offers a worldwide capability ready for deployment from its base in Scotland, 24/7/365, to the site of any allied, or even non-allied, DISSUB. Fully air transportable, the whole NSRS capability involves such elements as a modern free-swimming submersible, advanced tracking and communications, a portable launch and recovery system, as well as a high-sea-state launch and recovery capability, hyperbaric medical treatment facilities and more. The system is government-owned by the three participating states, but operated by contractors, currently with JFD at the helm. JFD coordinates and oversees maintenance, logistics and training, keeping the NSRS ready at all times and also managing any rescue.

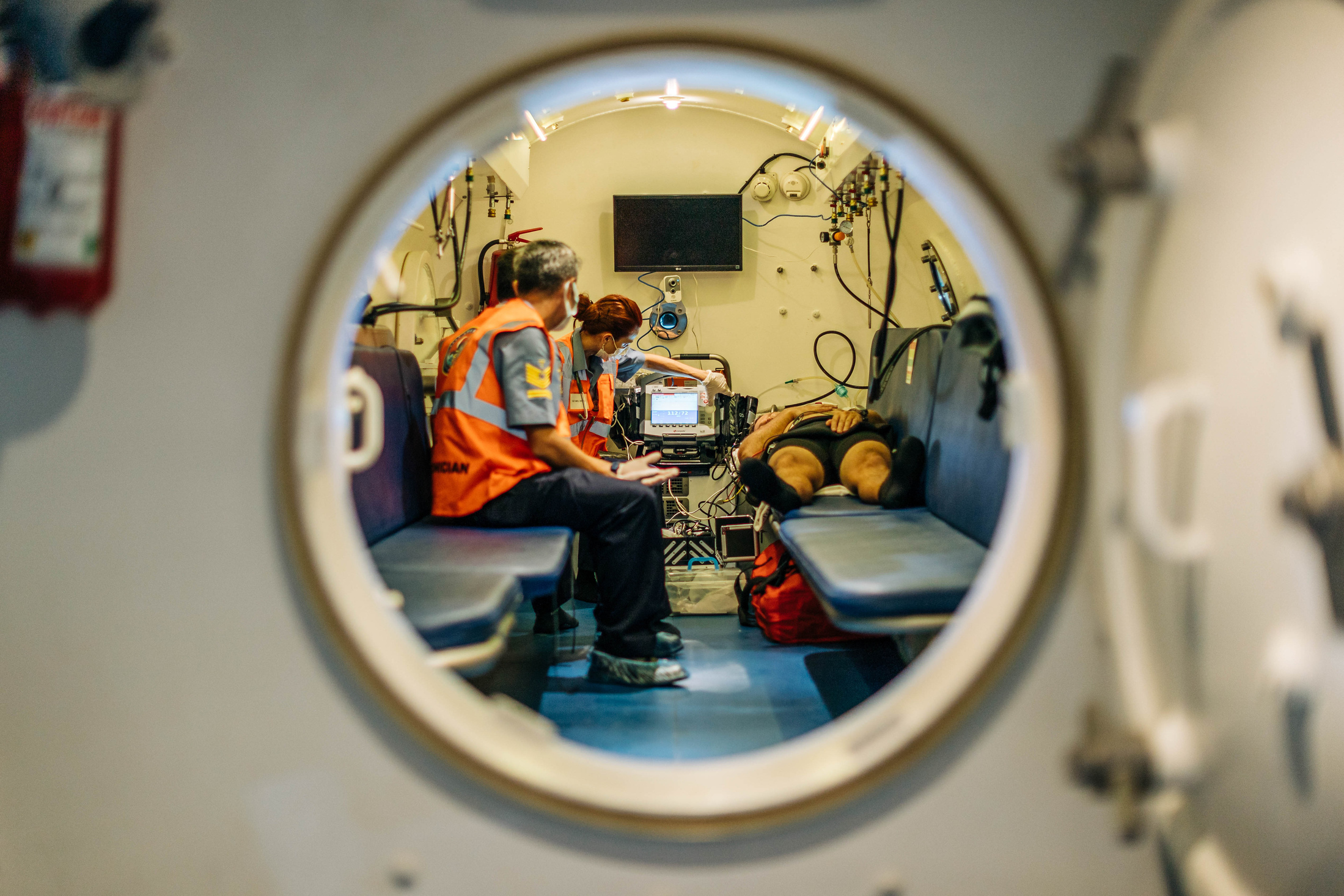

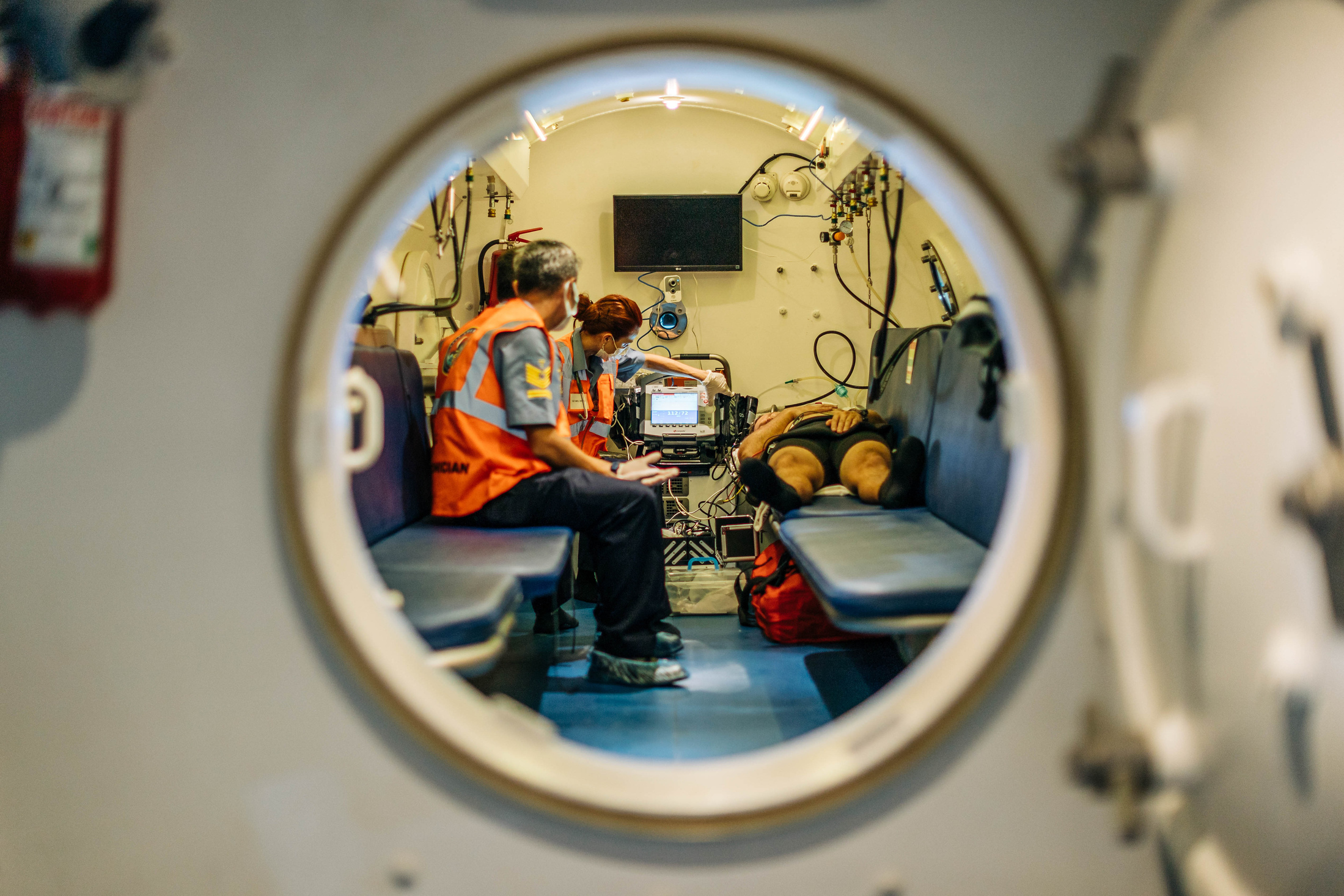

NSRS has two sub-systems, which can be mobilised independently of each other: the Intervention Remotely Operated Vehicle (IROV) can be deployed rapidly to a DISSUB to prepare the site for the arrival of the rescue system, as well as to provide life support. The larger rescue system comprises a free-swimming manned submersible, a Portable Launch and Recovery System (PLARS), a Transfer Under Pressure (TUP) decompression system, as well as ancillary support equipment.

Credit: NATO

When a situation occurs, RAF or commercial charter air transport is organised by the UK MoD, which also undertakes to locate and allocate Vessels of Opportunity (VOO) to operate with the rescue system on site, wherever that may be. On arrival by road to any port, elements of the NSRS will be embarked on a selected vessel, which becomes designated the Mothership (MOSHIP) before deployment to the DISSUB location. NSRS systems are designed for transportation aboard a variety of aircraft and MOSHIPS, as it’s not always possible to know just what craft will be available at the time of an incident, although suitable VOO are known on the International Submarine Escape and Rescue Liaison Office (ISMERLO) database and categorised according to their suitability as a MOSHIP.

At a rescue, JFD then manages such aspects as bridge operations, submersible launch and recovery, and piloting remote systems. Military support, such as medical aid and provision of Transfer Under Pressure System (TUPS) operators, is provided by participant nations, as well as other allies, if involved in the rescue effort.

ESD spoke with Ben Wright, Head of Capability, Submarine Escape and Rescue at JFD, (current NSRS prime contractor), for some insights into the evolving submarine rescue scene. He said that that all submarine rescue systems globally have different benefits and capabilities, and serve different purposes, with two types of rescue systems currently available to ‘customers’: ‘Regional’ Mothership (MOSHIP)-based solutions, such as one located in Singapore, and ‘Global’ Air Transportable Systems, as operated by the NSRS, Australia, the US and India.

Credit: JFD

A regional MOSHIP-based system will be permanently installed on a MOSHIP, immediately ready to sail to the location of a sunken submarine. A regional system can reach local submarine emergencies very quickly, but due to sailing-time limitations it has a maximum effective radius beyond which a viable rescue is unlikely. That said, being permanently mobilised on a Mothership means it can provide rapid response in small area of coverage with minimal planning and risk.

A global air-transportable system, on the other hand, will have worldwide coverage and be land based with a minimum mobilisation time for deployment to a vessel anywhere in the world in the event of an emergency. The shore-based system will use road and air transport for mobilisation onto its eventual vessel. “The pertinent words used within submarine rescue,” Wright said, “are Time to First Intervention (TTFI) and Time to First Rescue (TTFR), which address all phases of a response to an emergency.” Regardless of location, air-transportable systems aim to achieve a TTFR of 72 hours. He added, “In a DISSUB emergency, it is more than likely that multiple rescue systems would be deployed to improve the chances of a rescue.” Many nations, according to Wright, rely on help in a rescue situation as they do not have a rescue system and only limited capabilities of their own and it’s typically the Global Air Transportable systems that will be called on, but this does come with risks in terms of achieving viable TTFI and TTFR.

Credit: JFD

Wright said that JFD currently has long-term support and availability (24/7/365) contracts with Singapore, India (two systems), the NSRS and Australia and this also involves training exercises. “All of these support contracts require JFD to support global exercises conducting submarine rescue training.”

Generations of Systems

Of the several submarine rescue systems located around the world today, JFD has manufactured seven of them, with its latest 3rd Generation Submarine Rescue System, based in India, being the latest global flyaway system. This has features not present on the 2nd-generation systems (which are used, for example, by the NSRS), including a fibre-optic communications capability. Wright says the company has already begun development of its 4th-generation rescue system.

First-generation submarine rescue systems saw launch and recovery of SRVs using A-frames and divers becoming commonplace. Battery technology and through-water communications also improved making it possible to operate submersibles for extended periods, ultimately enabling the modern-day rescue cycle, including rapid mobilisation to a remote port for global operability. The first-generation United Kingdom LR5 SRV began as a diver lock-out submersible, but evolved through a series of upgrades and refits, including a new, all-steel hull, to become the first truly viable, free-swimming submarine rescue craft, with many of the features and technologies found on these early craft identifiable on today’s systems, though in refined or re-designed form.

Then, largely in response to the tragic Kursk incident in 2000 and successful Priz rescue in 2005, larger and predominantly nuclear-powered navies sought to increase submarine rescue capabilities and requirements called for higher-capacity rescue and decompression assets. This drove the development of second-generation systems. Improvements included a modular build strategy, allowing vehicle interiors, exteriors and hulls to be manufactured simultaneously, as well as having improved accessibility for through-life maintenance activities. Compared to earlier first-generation systems, these second-generation systems, including the DSAR-5 (Korea), DSAR-6 (Singapore) and NSRS (NATO), LR7 (China) and SRDRS (USA), have improved battery technology offering more power and endurance, including the ability to operate at greater depths, modernised control, navigation and communication systems, as well as fully integrated transfer-under-pressure capabilities.

Credit: JFD

While second-generation systems remain in full operation today, JFD’s third-generation submarine rescue system incorporates the capabilities of preceding generations, though with a focus on a lighter, more efficient design. Technical advancements of first-generation systems form the foundation of the fly-away, free-swimming SRV-centric system, accompanied by improvements in technology, practice and procedure found in second-generation systems aimed at optimising TTFR. For conventional navies and those with modest airlift capability, third-generation systems offer a significant step change in real world capability, as well as the ability to be integrated into a dedicated MOSHIP.

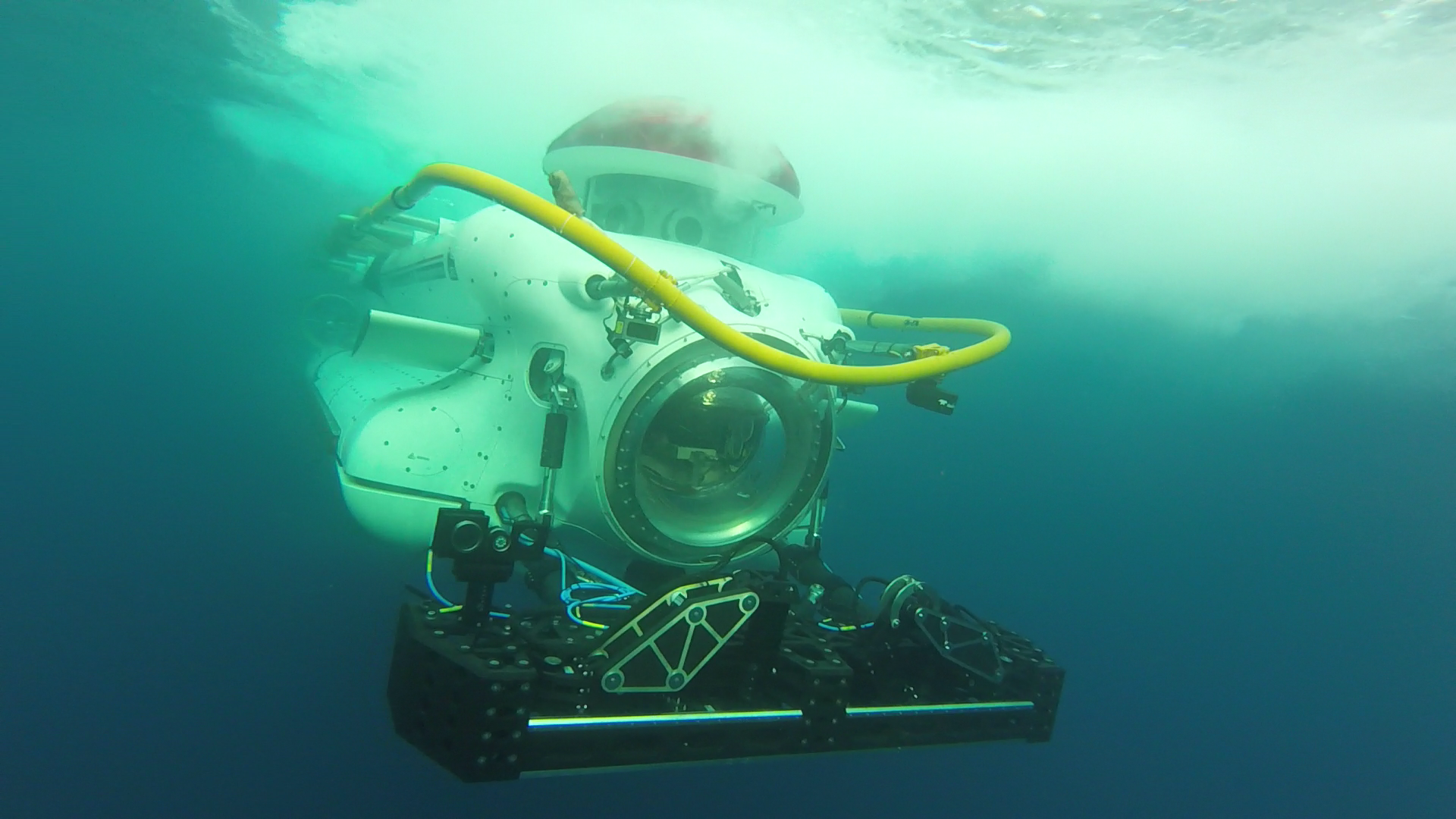

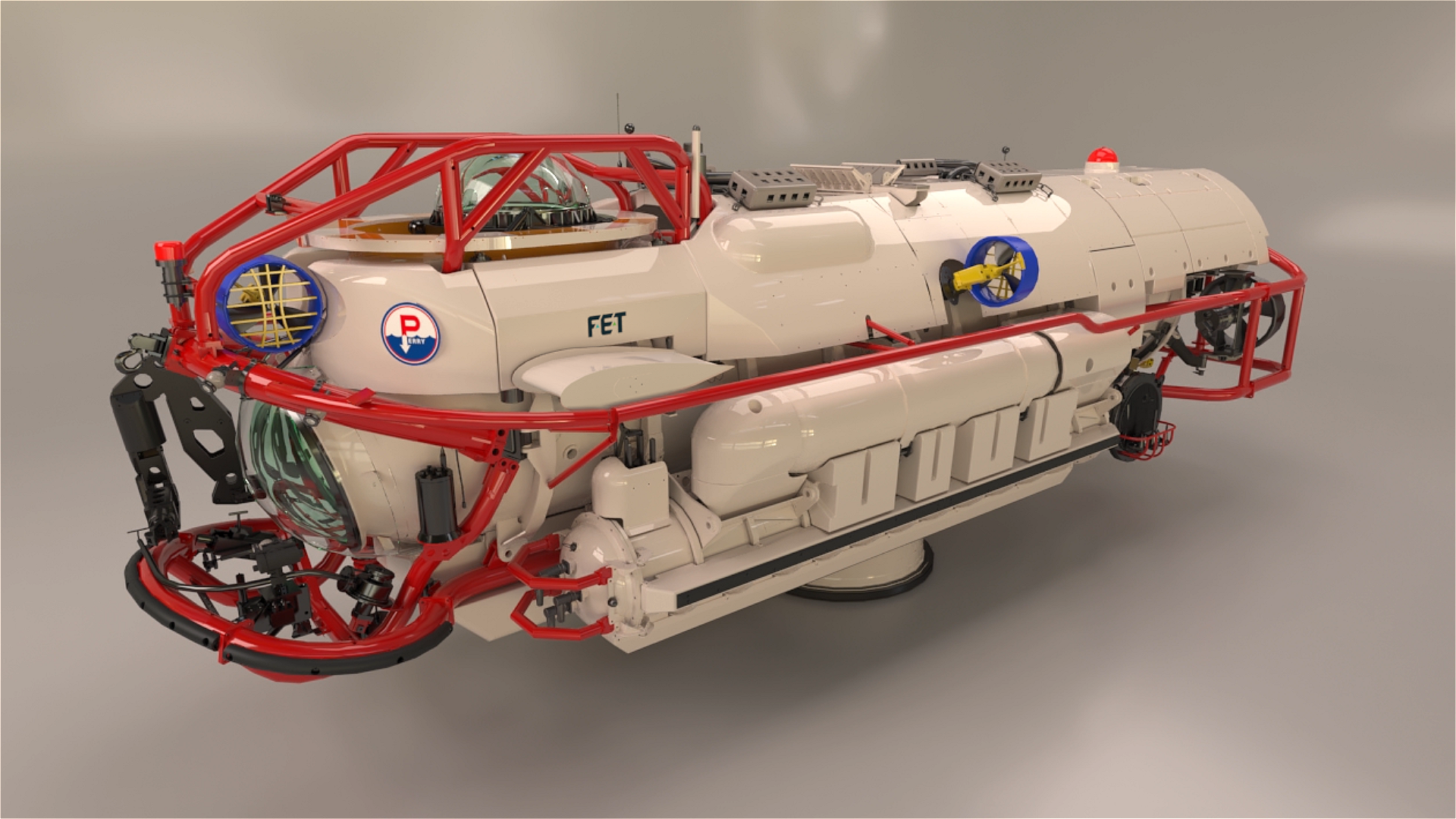

Another leading player in submarine rescue systems is Forum Energy Technologies (FET), which has previously delivered systems for the NSRS. Its latest SRV system was completed in November 2020 for a foreign navy in the Asia-Pacific region and has been built to the latest Lloyds design codes to facilitate full class certification. The system is being supplied with a Launch and Recovery System, an ROV system, simulator, emergency life support stores (ELSS) and other support systems.

The SRV can dive to over 600 m and rescue 17 submariners per dive. The advanced SRV completed sea trials in June ahead of its deployment to the customer. The trials tested the SRV’s capabilities to perform a variety of demanding operations, including deep dives, navigation, and mating with a target. In-country commissioning and testing took two months to complete. The new SRV is divided into two sections, a command module for pilots and a rescue chamber for the rescue chamber operator and those being rescued. It has increased power and an advanced auxiliary thruster control system that allows for speeds approaching four knots, which enables it to operate in strong currents. The vehicle is able to attach to submarines at angles over 40 degrees. It also incorporates advanced sensors and sonars to locate a distressed submarine as quickly as possible, including a doppler velocity log, fibre-optic gyroscope, and depth sensing systems.

Credit: FET

The ELSS containers in the contract are pressure-tight pods, nominally 10 kg negatively buoyant in seawater, used to deliver life-preserving stores to the crew until a full rescue can be mounted, either by a diver, an Atmospheric Diving Suit (ADS), an ROV or the rescue submersible itself. The ELSS pod is compliant with ANEP-85 ‘material interoperability requirements for submarine escape and rescue’. According to FET’s Vice President, Subsea Vehicles, Kevin Taylor, the SRV’s capabilities make it suited to a wide range of operations in the defence market and have received the Lloyd’s Register stamp of approval.

Although the number of players in submarine rescue remains small, navies worldwide are expanding their submarine fleets, increasing the demand for rapid submarine rescue capabilities. Development and maintenance of these specialist capabilities deserves greater attention by submarine operators, who may find themselves in need of such services.

Tim Guest