The latest developments in Lithium-ion battery (LIB) systems in the underwater domain have resulted in significant advantages for submarine operations compared to standard lead-acid batteries and have increased the number of new submarine procurement programmes.

The aim is to provide modern submarines with maximum tactical mobility, while at the same time reducing the indiscretion rate and increasing the submerged autonomy to deal with multi-domain anti-submarine warfare (ASW) threats. This article also looks at the latest achievements in the air-independent propulsion (AIP) systems, which contribute to extending underwater range and endurance at low speeds.

Higher volumetric and gravimetric energy density are advantages Lithium-ion technology provides compared to lead-acid batteries with the same volume. Another important benefit of LIBs is that they allow for greater utilisation of a vessel’s onboard capacity, which already generates greater submerged autonomy. Moreover, they charge more quickly, which means a reduction in the time the submarine is required to use its primary power source. They also have the ability to reach maximum speed no matter the state of battery charge. Finally, they can continue to be developed over time and gain performance increases, just as we see today in the world of e-mobility. However, these benefits come together with safety issues affecting the technology, requiring extensive safeguarding solutions for the overall submarine environment.

Germany

The thyssenkrupp Marine Systems (tkMS) company has reached the serial production phase milestone – to be launched in 2024 – of its 4th Generation Fuel Cell (FC4G), also known as the Advanced Submarine Fuel Cell (ASFC). The latter exploits the know-how accumulated in over 30 years of fuel cell (FC) technology development, with systems either contracted or in use with nine customers, totalling approximately 50 submarines worldwide. ESD understands that this figure of nine users refers to the eight users of tkMS’ current generation of FC AIP, including Germany, Italy, Portugal, Greece, Republic of Korea, Turkey, Singapore and Israel, while the ninth is expected to be Norway, which together with Germany, has awarded tkMS the joint contract for the supply of the new U212CD boats.

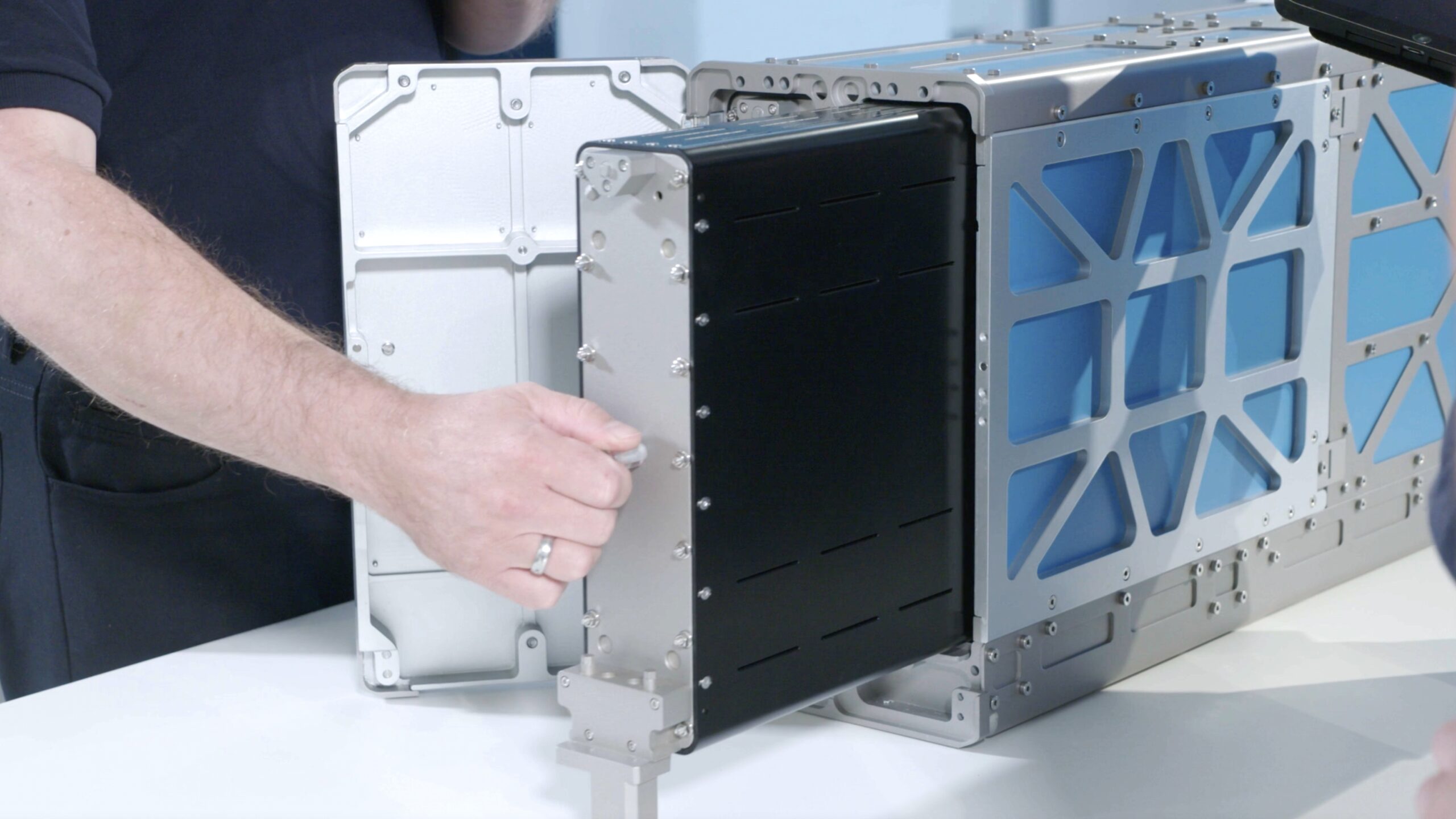

The ASFC is a new generation high-performance 320 kW (as baseline) AIP system characterised by high efficiency and reliability thanks to advanced Polymer Electrolyte Membrane (PEM) fuel cell technology, and a fault tolerant design. These characteristics, in addition to higher maintainability through modular build-up, easy accessibility and ‘hot-swap’-replacement of defective FC modules by means of onboard spares during a mission, noticeably increases operational availability, as the submarines do not need to return to homeport, tkMS explained. The ASFC also requires only moderate integration efforts due to re-using many existing components, the German company added.

Credit: tkMS

The ASFC is the result of an internally funded development programme that started in 2014, with the aim of registering the manufacturing of a functional demonstrator in 2016 at its test lab at Kiel shipyard, in addition to the testing of the first FC line system prototype in 2019 and the availability of the first serial production module in 2022. In order to qualify the system for submarine integration and operations, the international classification society DNV has monitored the design process and certified the system’s safety while operating as an independent third party. The company is continuing to run stress tests to ensure the ASFC’s availability. In parallel, tkMS has invested heavily in its own specialised fuel cell production site, also at Kiel shipyard, with a new and expanded production line to be completed later in 2023.

Based on the latest PEM technology and fuel cell stacks developed and produced by tkMS with membrane electrode assembly supplied from different component vendors, the new generation ASFC works by feeding liquid oxygen (LOX) and high purity hydrogen into the cell, generating electricity. The oxygen is stored on board in liquid form, while the hydrogen is stored within metal-hydride cylinders. Aside from electricity, the only by-product of the reaction is pure water, which can be stored on board as ballast and subsequently pumped overboard as needed.

The new ASFC is based on a baseline 40 kW FC Stack of simple, cost-effective design with a long service life, two of which are integrated together into a so-called ’line system’. This includes the gas humidification and recirculation equipment, while the ASFC suite is composed of up to four FC line systems for a total of 320 kW, providing a quiet, safe, reliable, and compact system, independent of diving depth, and with very low oxygen consumption, according to tkMS.

The ASFC system is integrated with a reliable high-energy Lithium-ion-battery package offered by the same company, that leads to a substantial increase in submerged range and speed. The German company along with French company Saft has finalised the joint development of a LIB system for the U212A class of submarines. This is based on an R&D contract signed with German procurement agency BAAINBw in 2017, which saw prototypes being readied for testing in November 2021, followed by project completion in 2022, with the first installation planned for 2023.

Credit: tkMS

Type approval has been successfully conducted in cooperation with BAAINBw. Apart from the usual tests that include shock, EMC, magnetic, environmental tests and similar, the system has undergone extensive testing, accumulating more than 30,000 hours of operation. The safety standards have been officially certified by TÜV Rheinland, an international testing and qualification institution. In addition, the batteries have undergone various tests to prove they pass all necessary safety regulations.

France

French Naval Group offers a full LIB system for conventional submarines, responding to the latest operational needs. According to Naval Group, the aim is to provide modern submarines with maximum tactical mobility, while at the same time reducing the indiscretion rate and increasing the submerged autonomy to deal with both airborne and surface ASW threats. The battery remains the main power source of conventional submarines; the operational advantages of the LIB already exceed those of the lead-acid batteries, and are projected to evolve further over time. The shipbuilder has been studying the integration of this technology on board submarines, in particular the Scorpène class and later on the conventionally powered version of the Suffren class nuclear attack submarine, while ensuring safety and meeting operational requirements since 2006.

After a technical feasibility study completed in 2013, Naval Group was selected and partnered for the development of the LIB system with French company Saft in 2016, with the premise of safety, associated in this case with maturity and industrialisation, in addition to a track record and experience in battery systems. Related to this selection, electronic, mechanical, and thermal qualification had to be carried out to ensure its successful integration on board a submarine. In 2019, a first version of the system was qualified, and in 2020, a LIB system was integrated in an environment representative of a submarine with the appropriate level of preparation.

Credit: Naval Group

The LIB complies with Naval Group’s technical standards for submarine design and shipbuilding, including the high demands of nuclear safety and diving safety rules. The system also complies with all international standards associated with electrical systems such as IEC among others, Naval Group claims. The latter is today ready to integrate this technology on board a submarine, focusing on continuous improvement to take advantage of all the benefits this technology can offer.

Italy

Under the U212 NFS (Near Future Submarine) AIP submarine programme, in February 2021, the Organisation Conjointe de Coopération en matière d’ARmement

(OCCAR) awarded Fincantieri a contract for the development, construction, initial support for the first five years, and integrated logistics support for the first two boats to delivery, respectively in December 2027 and January 2029. The same contract also includes the development and production of a new training centre and the development of a new LIB by national industry. Construction of the first boat was launched in January 2022 while the second followed in June 2023. In the same month, the Italian Parliament also approved the procurement plans for the third and fourth boats. The contract option for the third submarine acquisition was exercised in July 2023.

Based on the successful operational and industrial experience developed under the joint U212A programme with Germany and the stringent timeline to replace the first batch of two Sauro class boats, the Italian Navy and MoD decided to develop and put into service an evolved U212A design boat. This will be characterised by a high degree of national contribution, including the integrated platform control system (IPCS), combat management suite, weapons package, and the new generation LIB.

The latter development officially started in 2015 through different subsequent national research programmes, aimed to define the most suitable technology, choosing lithium iron phosphate (LiFePO4) as the most suitable chemical compound to ensure safety. The results of the research programmes have been integrated in the LIB development programme, as part of the U212 NFS programme contract signed in 2021. Under the control and support of OCCAR and Italian Navy experts, the national industrial team, including the FIB-FAAM company (Seri Industrial group), the Power4Future joint-venture between Fincantieri SI and Faist Electronics and the Fincantieri’s Cetena company finalised the design of the whole battery system, under the supervision of TÜV Rheinland. The latter is responsible for control and validation of the whole development and qualification process.

In summer 2023, hardware and software prototypes and functional mock-up were due to become available for production, testing and certification activities, with the aim of completing the development phase by the end of 2023. OCCAR, the Italian MOD and Navy plan to positively review and greenlight the follow-on phase 2 by the beginning of 2024, during which the complete LIB system will pass the land-based battery test laboratory qualification before installation on board the first-of-class boat for harbour and at-sea trials.

Credit: OCCAR

The new energy storage and management system has been developed to use the same dedicated compartment and interfaces used on the in-service U212A boats, allowing the system to be installed on board the latter submarines during the mid-life updates, extending their life cycle and providing operational benefits. While the contracted U212 NFS boats maintain the same tkMS/Siemens FC AIP used on the U212A class submarines, Fincantieri is working on a new-generation FC AIP, based on national technologies and industry developments. As the prime contractor, whole platform integrator and shipbuilder of the new U212 NFS, Fincantieri continues to develop new technologies and equipment for submarine and underwater applications. Among these, the propulsion and energy storage R&D activities to be launched include nanomaterials for hydrogen generation and a new electrical distribution system, in addition to the LIBs and the new-generation FC AIP as implemented on board the Zeus naval platform for zero emission propulsion testing.

Spain

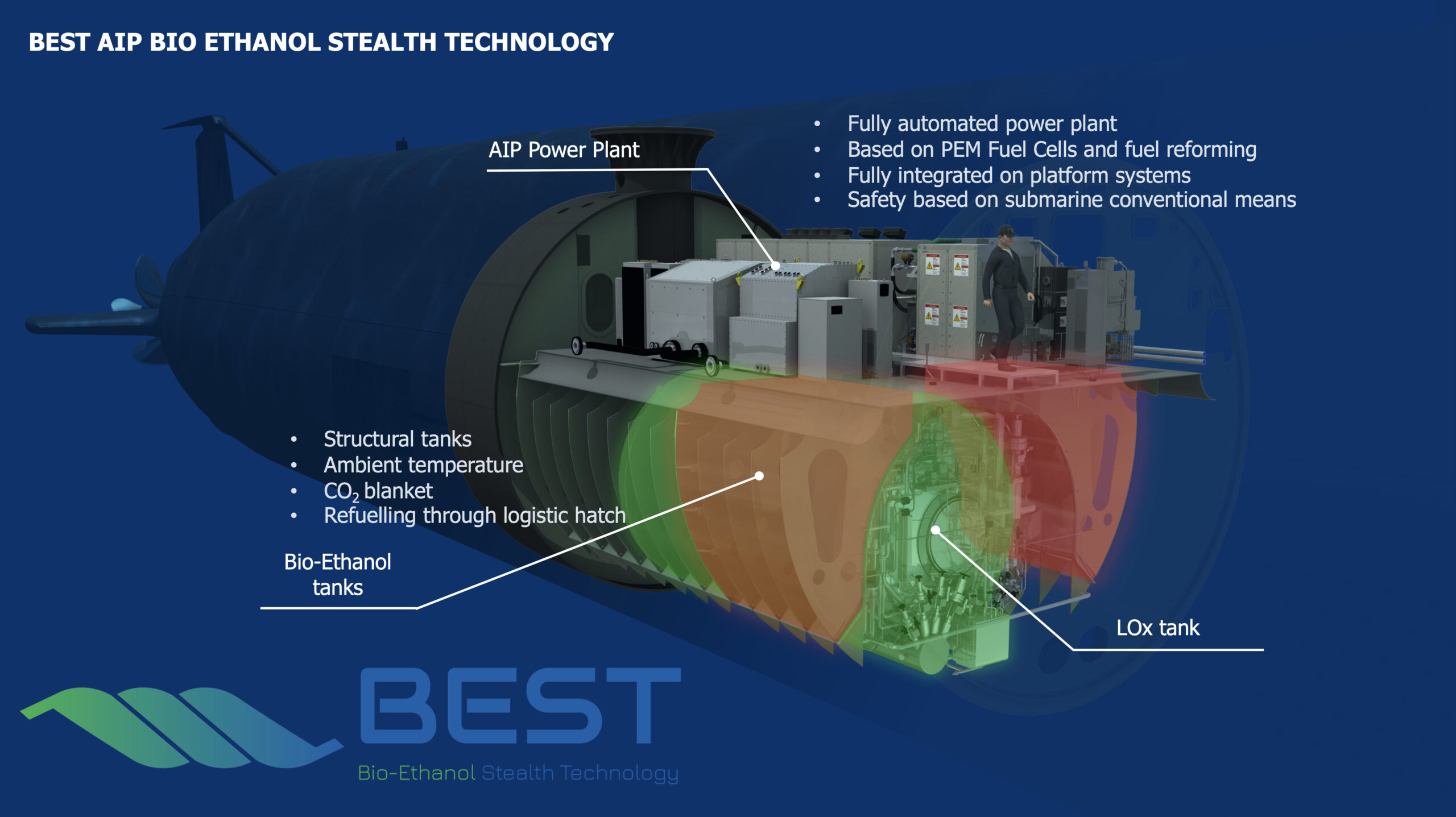

At the end of March 2023, the first-of-class Issac-Peral AIP submarine, developed and built by Navantia under the S-80 Plus class shipbuilding programme, successfully carried out its first static dive as part of the test schedule which will continue until its delivery to the Spanish Navy, planned for November 2023. The S-80 Plus class platform has been designed with a propulsion plant including a 300 kW FC AIP system and the Bio-Ethanol Stealth Technology (BEST) suite.

Developed by Navantia in collaboration with the Spanish Navy, Spanish companies Abengoa and Bionet, as well as the US-based Collins Aerospace, the new FC AIP is supplied with hydrogen produced on-board through a bioethanol reformer from agricultural bioethanol, readily available worldwide. The highly thermal efficient miniaturised bioethanol processor developed by Abengoa is fed with bioethanol fuel and oxygen, both of which are stored on board in liquid form, generating hydrogen and carbon dioxide as byproducts. The resulting hydrogen, along with oxygen are fed into the PEM FC provided by Collins Aerospace. The latter cell stacks are made of porous bipolar plates for passive water management and continuous membrane humidification. According to Navantia, this means there is no need for a humidification or liquid water removal system. This makes the fuel cell design simpler and provides double the service life compared to the market standard operating on reformate gasoline and pure oxygen, said the company. However, the bioethanol reformer process produces a stream of highly concentrated carbon dioxide and other gases, which are managed by the Carbon Dioxide Disposal System developed by Bionet, in collaboration with Navantia. This system dissolves the gaseous byproducts in seawater, which can then be pumped overboard in liquid form rather than being vented directly in gaseous form, thereby not giving away the submarine’s position.

Credit: Navantia

The ‘BEST’ AIP’s capabilities have been demonstrated with long-term tests and operational mission profiles at a dedicated land-based facility at Cartagena shipyard. The suite is housed in the hull section of the S-80 Plus class boats, and includes the fully automated AIP power plant and auxiliaries on the upper deck and the structural tanks for the bioethanol and the single LOX tank – which can be refuelled through a logistics hatch in the lower compartment. These activities have confirmed a submerged endurance of up to three weeks, being fully operational through the full platform depth range, from tropical to sub-arctic environments. The new AIP has been designed for no major component substitution between overhauls (six years and over 5,000 hours), while components can be loaded or replaced through the logistics hatch, according to the Navantia.

The first platform of this class to be equipped with the ‘BEST’ AIP will be the third boat, which is planned to be delivered in early 2026. The first and second platforms were completed with the AIP section equipped with the lower tanks and other systems, but not the AIP suite, whose components will be loaded and assembled through the logistics hatch during the boats’ first major overhaul.

Sweden

Saab Kockums’ Stirling engine is one of the most proven AIP systems, having been developed and tested since the 1970s, and operational on submarines since 1989. The Stirling is a self-contained external combustion engine operating on a closed regenerative thermodynamic cycle. Low-sulphur standard diesel fuel from onboard tanks and LOX also stored in tanks, are mixed in a high temperature burner to generate temperatures of around 750 °C. This acts as the heat source for the engine, causing expansion of helium stored in a sealed chamber, with the gas being driven through a repeating sequence of thermodynamic changes. By expanding the helium to push against a piston and then drawing the gas into a separate cooling chamber for subsequent compression, the heat from the external combustion of diesel and oxygen can be converted into work. This in turn can then be turned into electrical energy by a DC generator, which charges the battery. As the Stirling engine is known to operate at a pressure of 20 bar, this limits the submarine’s maximum depth to 200 m, unless an exhaust gas intensifier system is used for deeper operations.

Each Stirling engine can produce 75 kW of energy, with two or more installed on each submarine in sound-insulated and rubber-suspended complete AIP modules, including the oxygen tank and auxiliaries. This offers redundancy and can be maintained at sea. The submarine’s operational readiness can be restored in just a few hours, by replenishing the fuel and LOX (including at sea), which reportedly gives the submarine platform the capacity for over two weeks of AIP operation at a speed of 5 kn without requiring snorting (also known as snorkelling). This has contributed to the Stirling AIP finding international success, equipping not only vessels of the Swedish Navy, but the upgraded Archer class submarines delivered to the Republic of Singapore Navy. It was also selected by the Japanese MoD and is locally licence-built by Kawasaki Heavy Industries to equip the Japan Maritime Self-Defense Force’s (JMSDF) Soryu class submarines, operational since 2009.

Credit: Saab

Starting from the Gotland class boats’ post mid-life upgrade programme, the Swedish submarines are equipped with the latest generation of Saab Kockums’ Stirling AIP modules. The latter equips the newest Blekinge class A26 AIP submarines for the Swedish Navy, where the complete propulsion and energy system is optimised for covert operations. The latest Stirling iteration is also being promoted as baseline equipment for the A26 Pelagic/Oceanic family platforms being proposed on the export market. The latest-generation Stirling AIP modules bring a number of enhancements including a reduction in overall volume and more energy per unit of volume, due to improved packing and shared components. This comes in addition to greater operating efficiency thanks to an enhanced heat recovery system, an improved exhaust system which enables deeper diving, and a new control system, which altogether translate into longer underwater operational endurance.

Alongside these developments, Saab Kockums, together with the Australian PMB Defence and Dutch EST-Floattech companies, has completed a project to develop a LIB suitable for installation on conventional submarines. The project was funded by Sweden’s FMV procurement agency,

India

In June 2023, the Indian Defence Research and Development Organisation (DRDO) and the Larsen & Toubro (L&T) group formed a partnership to develop and produce an indigenous AIP System for Indian Navy submarines. The L&T company is the recipient of the Transfer of Technology (ToT) of the Phosphoric Acid Fuel Cell (PAFC) AIP system developed by the Naval Materials Research Laboratory (NMRL) of India’s DRDO. This technology has been successfully developed with the support of industry partners L&T and Thermax, and according to the DRDO, it has reached the stage of maturity for mounting on-board select platforms.

Credit: DRDO

According to the joint press statement, under this collaboration, two AIP system modules are being developed for the Kalvari class submarines. The latter have been built locally by Mazagon Dock Limited (MDL) shipyard together with the French Naval Group, which provided the technology transfer and support for local construction of the Scorpène submarine design. In January 2023, an agreement was signed between senior officials of NMRL and Naval Group France to extend the cooperation, entering into the detailed design phase for the integration of the PAFC AIP system developed by NMRL for the Kalvari class submarines. As part of the agreement, Naval Group France will certify the AIP design for integration in the submarines. In July 2023, the Indian MoD announced approval for the procurement of another three Scorpène submarines in addition to six contracted – five of which are already in service and the sixth is due to be in service in 2024.

Japan

Japan’s MOD and the JMSDF have been global frontrunners in the development of a LIB solution and its first operational application. For years, the JMSDF has also evaluated Saab Kockums’ Stirling engine on board its training boat as an AIP system for its latest underwater platforms, before equipping its Soryu class with the new system. The Japanese MoD introduced LIBs on board its submarines after a lengthy development and testing period, which began in 2002.

The GS Yuasa Technology Corporation (GYT) and Mitsubishi Heavy Industries (MHI) signed a contract with Japan’s MoD Acquisition, Technology and Logistics Agency (ATLA) in 2015 for the delivery of a whole LIB system, including the main storage battery management and safety control device for submarines. GYT started mass production of LIB batteries in March 2017 and delivered them to MHI in August 2018. The first Soryu class submarine to be equipped with the LIBs was the Oryu (11th boat of the class), with the main battery storage and battery management system integrated on the submarine from summer 2019. With its baseline Stirling engine-based AIP system, the boat was commissioned in March 2020, with the JMSDF becoming the first Navy in the world to use a submarine equipped with LIBs.

The last (and second) boat belonging to the Soryu class similarly equipped was commissioned in March 2021. In the meantime, starting from the mid-2000s, the Japanese MOD and JMSDF have been studying a next-generation submarine class exclusively equipped with LIBs. This paved the way for the Taigei class platforms, whose first-of-class vessel was commissioned in March 2022, and is now used as a test platform.

Credit: GYT

With the same dimensions, but with a slightly higher displacement compared to the Soryu class, the new and stealthier Taigei class are equipped with a more capable combat system and sonar suite, alongside a propulsion plant with a new snorkel-equipped power generation system and a more powerful energy storage and management system.

Reportedly based on the same design as the Soryu class, and featuring an undisclosed higher number of batteries compared to the previous class according to local news sources, the new energy storage and management system provides longer endurance at higher speeds, which allows the vessels to patrol the vast waters around Japan more quickly than their predecessors. According to a 2017 UDT presentation provided by a former JMSDF Fleet Submarine Force commander, the JMSDF has been receiving lithium nickel cobalt aluminium oxide (Li-NCA) type batteries already provided by GYT for the Soryu class submarines, although no official statement has been released.

A document dated December 2020 and jointly elaborated by GYT and MHI, provides a LIB development overview, referring to them as the lithium cobalt oxide type of LIB. Results published in GYT’s 2022 report presentation noted the “supply (of) trials products of Lithium-ion batteries for next-generation submarines”, which is understood to refer to new or more capable batteries providing extra energy and endurance.

South Korea

On 30 March 2023, South Korea’s DAPA (Defense Acquisition Program Administration) held the keel laying ceremony for the first KSS-III Batch II submarine at the Hanwha Ocean’s (previously Daewoo shipbuilding & Marine Engineering, DSME) Okpo shipyard. The KSS-III Batch II boats are the second generation of the 3,000 tonne class of locally designed and built AIP submarines, and which differ from Batch I (first generation). Batch II boats have a longer hull (5.8 m) and heavier displacement (3,600 tonnes) with reduced acoustic signature, together with a more capable propulsion plant with extended endurance, alongside longer detection range underwater sensors and expanded precision strike capability, with 10 vertical launch cells compared to the six on the first generation.

The KSS-III Batch II submarines are equipped with an AIP propulsion plant based on MTU12V4000U83 diesel engines, a PEM FC AIP (already installed on Batch I boats), and for the first time a LIB system. No information has been released on the FC AIP, but according to local media reports, the KSS-III programme boats are equipped with a locally-developed AIP based on four PEM fuel cells provided by Bumhan Industries. These each generate 150 kW, fed with oxygen (stored as LOX) and pure hydrogen (stored in metal-hydride cylinders). In 2019, South Korea’s DAPA chose Hanwha Defense as the supplier of LIBs for the KSS-III Batch II submarine programme. The latter passed rigorous tests under extreme conditions of fire exposure and suppression, saltwater immersion, short circuit, shock, electromagnetic compatibility (EMC), electromagnetic interference (EMI), and heat, while full scale (battery group) demonstrations were conducted at a dedicated land-based test site. Cells come from Samsung SDI and are based on commercial off-the-shelf (COTS) technology, similar to cell phone batteries.

Credit: Hanwha Defense

The new battery technology will improve energy efficiency, offering better energy density, battery life and underwater endurance compared to the preceding lead-acid battery technology. Hanwha Defense Li-ion batteries reportedly provide 160% more endurance (longer output) at economic speed and 300% more endurance at maximum speed. Lithium-ion batteries also provide double the amount of charge cycles (up to 4,000 cycles – or approximately 10 years of operational life) compared to lead-acid batteries. The first KSS-III Batch II boat will be launched in 2025.

After a couple years of trials, its delivery to the ROK Navy is currently planned for 2027. In February 2022, the South Korean Agency for Defense Development (ADD) announced the development of a methanol reforming plant for submarine fuel cells, which can improve submerged performance through hydrogen production on board the submarine, showing a system developed by DSME, today Hanwha Ocean. This technology, according to the ADD, is expected to greatly contribute to improving the performance of domestic submarines in the future.

Running Silent

As improvements in battery technology and AIP continue, conventional submarine performance remains on a consistent upward trajectory, with modern variants offering improved endurance, quieter running, and better safety compared to previous models. The market has grown to include a large number of contenders, offering a plethora of sophisticated and capable battery technology and AIP system options. As such, the market now offers perhaps more options than ever before for Navies to procure highly-capable conventional submarines.

Luca Peruzzi