Decontamination is a core function in both military CBRN defence and civil protection against terrorism. In both missions, decontamination (“decon” in the industry’s jargon) is the technical process by which threat materials on a surface (“contaminants”) are removed and/or neutralised.

There are many components of decontamination technology and systems, which exist for vehicles and heavy equipment, people, and specialty purposes. This article examines so-called “mobile decontamination” systems. Although specialist definitions may vary, for the purposes of this article, such systems are defined as vehicles, trailers, or containers and skid systems designed to be fitted onto trucks, specifically intended to provide personnel or equipment decontamination for military or civil missions.

One can argue that such skid or container systems are not “mobile systems” but many are designed specifically to fit onto the user’s existing fleet of trucks. Indeed, such systems are the heart of the military mobile decontamination business. It should be noted that large mobile systems tend to sit at the top of deep product lines involving smaller elements and components, many of which are useful products in their own right for smaller missions.

A brutal commercial truth in the military CBRN defence market segment is that mobile decontamination systems are large, expensive, and long-lasting. If well maintained and not overworked, such systems can often last for many decades. Decontamination systems procured by the US Army in the 1980s soldier on. Others atrophy from under-utilisation, as scenarios requiring their use are thankfully scarce. As such, this sector of the market often lacks major contracts for months or years at a time.

Vehicle Decontamination

Mobile decon systems generally address two particular operational requirements. The first is vehicle and heavy equipment decontamination. A bit like a mobile car-wash, large decon systems set up decontamination stations which wash down major military vehicles like tanks, trucks, and artillery pieces. While myriad chemical products are available from the various manufactures, soap and warm water are often the mainstays of this mission. The other main mission is personnel decontamination. While this may sound sophisticated, for most purposes this means “take a warm shower with some soap”, and many mobile decontamination systems are quite popular in major exercises because they represent warm showers to tired and dirty soldiers.

The Market

Most of the decontamination market has historically faced competition from generic equivalents. In the civil protection market, mobile decontamination systems are up against serious generic competition in the form of firefighting apparatus. Fire engines have long been used for both improvised and specialist decontamination tasks.

While it is taken as truth by many that the United States drives the world’s military CBRN market, mobile decon systems is certainly an area where European companies are serious players. Any serious analysis of this market segment in Europe will always come back to three main firms, one Italian and two German. Cristanini (Italy), Kärcher (Germany), and OWR (Germany) are the main pillars of large, mobile decontamination systems in the EU. It should be noted that all three firms are not just manufacturers of major decontamination systems, but smaller systems, accessories, and chemical solutions for decontamination, as discussed in previous issues of this magazine.

Christanini

Taking them in alphabetical order, Cristanini S.p.a. is located in Rivoli Veronese, near Verona, Italy. Founded in the early 1970s, Cristanini still strongly bears the imprint of its founder, Adolfo Cristanini, who has been a fixture at many trade shows and exhibitions for decades. Cristanini works in connection with the University of Padua to keep its technologies up to date. The author has visited the Cristanini plant several times and it is an impressive operation. Like its two German rivals detailed below, Cristanini serves other sectors of the decontamination market as well as more conventional cleaning and spraying markets.

Working from smaller to larger, the “Light Decon Trailer” is based on Cristanini’s smaller Sanijet and Sanigun systems. As the name suggests, it is a light trailer (1385kg fully loaded) that could be pulled by virtually any reasonable military vehicle. One person can operate this system to perform vehicle or equipment decontamination operations with its high-pressure hot water spray. It can also fold out to provide a single shower lane, with warm water and appropriate pressure for personnel decontamination.

The next step up in the product line is the 2200kg “RI/CBRN trailer.” It is longer and higher capacity than the Light Decon Trailer. This system has a rated capacity of up to 12 vehicles per hour, although this will definitely depend on size of vehicles. It can support an optional inflatable decon tent for stationary personnel decon of up to 120 persons an hour. Interestingly, it can also be pulled to support terrain decon, deconning a 5-meter-wide lane at about 4 km per hour, if water supply is topped up.

Mobility

Moving up from trailers to full-size vehicles, the Cristanini TMAV “Tactical Multi-mission Air-transportable Vehicle” is a multi-role decontamination and firefighting vehicle. It is a 4×4 truck, which can fit on a C-130J cargo aircraft. With a “cherry picker”-style aerial platform and the Sanigun system, it can decontaminate 3 aircraft or 6 vehicles per hour. Like the trailers, it can operate in stationary mode as well for personnel decon, with a foldable tent. In this mode, it can decon 25-30 people an hour. As additional non-CBRN missions often help customers make buying decisions, the TMAV is also useful for aircraft de-icing and some firefighting roles.

The DDMAS represents Cristanini’s largest mobile system. A critic would argue that the DDMAS is not a mobile on its own. However, it’s a full system skid specifically designed for either temporary or permanent mounting on a military cargo truck chassis. It has the telescoping arm of the TMAV. One operator can decontaminate from the arm and another can decontaminate from ground level. As with the other systems, personnel decon is supported by tented systems. The DDMAS has enough pumping infrastructure to support several decon tents. It can also support firefighting operations, terrain decon, and even undercarriage decon of vehicle chassis.

Kärcher Futuretech

Moving on to Germany, Cristanini has not one, but two competitors in this space. Kärcher Futuretech is based in Schwaikheim, Germany. Many readers may be familiar with Kärcher pressure sprayers and pressure washers for civilian use. Their military business extends to water purification, mobile catering, and mobile camp infrastructure. But within military circles, the Kärcher name is well-known in military CBRN decontamination.

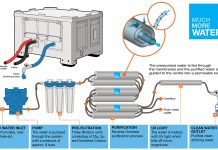

Two products form the core of Kärcher Futuretech’s mobile decontamination line-up. Both are container-based systems, designed to be installed on any military’s standard light or medium cargo truck platform. The smaller of their two systems is based on a 10-foot cargo container. Weighing 4000 kg with an integrated generator and 1000 litre water supply, the DSVP 10C can fit on numerous different military vehicle platforms. This system can be put into operation within minutes. It can be operated by a small crew and is capable of operating for one hour before needing more water. In that time, it is rated for decontaminating 19 people, 2 vehicles, or 150-200 square metres of terrain.

Larger Scale Military Mobile Decontamination Systems

The much larger Decocontain 3000 is based on a 20-foot cargo container. Fully loaded, it weighs 12000 kg, much of it from the 2700 litres of water storage. It can be operated by 8 decontamination specialists and takes less than 20 minutes to set up for full operation. It can support decontamination of up to 160 people or 8-12 vehicles, depending on size. This raises a valuable point. The answer to the question of what number of vehicles per hour can be decontaminated will vary greatly in practice. A LEOPARD tank, a PATRIA APC, and a Landrover will all have quite different surface areas and take different times, regardless of which vendor made the decontamination apparatus. This system is in military use in at least Sweden, Singapore, the UAE, Oman, Spain, and Kuwait.

Another Kärcher product offering is the TEP-90. Not dissimilar to the Decocontain, it is based on a 20-foot container but also integrates a crane arm which can also serve as a platform for a decontamination specialist to spray water or decontamination solutions. Israel is known to possess the TEP-90 and it serves with the CBRN troops of the Bundeswehr.

It is also worth noting Kärcher has a specialty mobile decontamination system called the DSSM. This system is also based on a ten-foot container. It is designed for the more specialised task of decontaminating personal equipment such as helmets, body armour, and weapons, as well as sensitive equipment like electronics. The DSSM uses either vacuum chambers or hot gas decontamination, depending on the material to be treated. This system is in use with the Germany military.

OWR

The other big German name in this market is OWR, which is short for Odenwaldwerke Rittersbach GmbH. They are based in Elztal-Rittersbach. OWR has long been a rival to Kärcher and Cristanini in the global CBRN decontamination space. As with the others, OWR makes a variety of smaller systems as well. They are well known in this space for their GD-6 decontamination agent, mentioned in previous issues of this publication.

OWR’s primary contribution to this market segment are the MPD-100 and MPD-109i. The MPD-100 is based on a 20-foot cargo container and works either as a roll-on/roll-off system or permanently integrated into a truck platform. The MPD-100i is an improved version with more capacity. The MPD-100 can be operated by as few as 3 operators, although throughput is enhanced by a larger crew. This system is designed for all of the major types of military CBRN decontamination and can operate with both specialty and generic decontamination chemicals. (To be fair, so can the other manufacturers’ systems although this is often not advertised.)

The MPD-100 and MPD-100i have fairly impressive throughput specifications. The MPD-100 decontaminates up to 120 personnel an hour (double that in the MPD-100i). Various options and accessories make casualty decontamination possible as well. Unlike some of the other manufacturers, OWR breaks down the figures on vehicle decontamination by class. It claims up to 5 main battle tanks, 10 trucks, or 20 light vehicles per hour. Terrain or infrastructure decontamination (such as runways) is rated at 6,000 square metres per hour. It should be noted that OWR also made a smaller, trailer-based decontamination unit but it is not in the current product line-up on their website. Their legacy systems are well supported for decades, however.

Smaller Players

Although these three are the most prominent players in the European CBRN space it is important to note that there are some other manufacturers, who often serve their own domestic defence markets. Their success in export markets is quite variable. Excalibur Army (CZ) produces their Decon vehicle, based on a Tatra 4×4 truck. It features a 2 man boom lift platform. NBC-Sys (France, now part of NEXTER) has the “Dekvoz” which has seen service in the Slovak army. Their “Symoda” is designed for aircraft decontamination, and their “Meerkat” is a small decon vehicle, designed for small missions like one vehicle or 5-6 personnel.

A Polish consortium produces the “APIS-2” decontamination vehicle and won a contract to deliver 26 to the Polish military. Hotzone Solutions (NL) advertises that it can modify vehicles and adapt them for decontamination use. Utilis (France) and Hispano-Vema (Spain) have various container-based products which don’t quite match the threshold for this article.

To a greater or lesser extent, requirements by customers often necessitate a reasonable degree of customisation. All of the major vendors described above do modifications to allow their systems to fit onto vehicles or even integrate their systems onto specific vehicle platforms. There is enough expertise in these companies that they would generally be competent to make specialty or bespoke systems for a particular agency or national requirement.

Outlook

Where does the future lay in this segment? It is this author’s professional judgement that it is actually quite hard to tell. At the end of the day, CBRN decontamination in such large roles is as much about putting warm soapy water onto the problem as it is about anything else. The products and technologies are all mature. Future development in this market will largely be a matter of militaries taking the CBRN threat more seriously or not. If they do, then there will incremental growth in this sector.