Governments and their respective authorities have been increasingly setting industrial participation requirements over the last years, which in many cases are mandatory criteria for being awarded a contract in the sphere of the defense industry. Currently, more than 100 countries worldwide require some form of localization projects in their defense acquisition programs.

The idea here is that major defense contracts are usually multi-billion investments through which countries wish to meet political, economic, and defense objectives by promoting military and technology self-efficacy, and taking advantage of the local industry being participated at least partly. In most cases, the prime contracts are handed to the global defense players, so the responsibility to create concepts and fulfill the requirements lies with them.

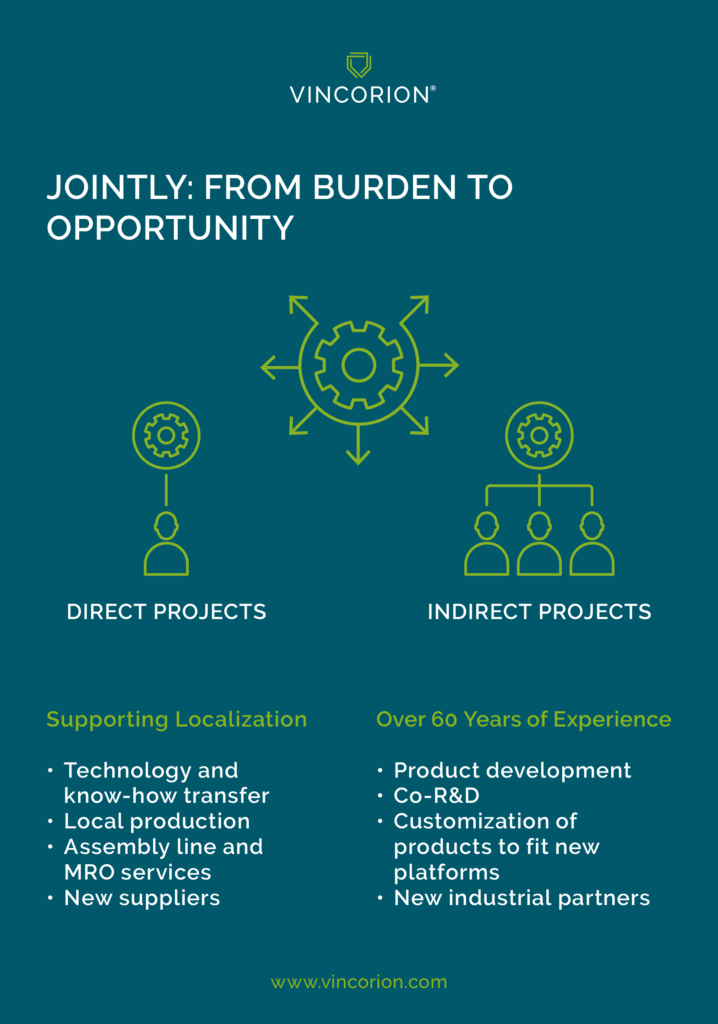

VINCORION with its long history in the defense and aviation industry and wide range of competencies in power generation and the management of electrical power is a company that offers its solutions to both: OEMs and governments. And since the defense landscape is very competitive, one can barely survive without forming partnerships and cooperating with other companies globally. Thus, the topic has already become of high importance to VINCORION in the past.

A Chance to Partner up

Prime contractors often request support from their suppliers to fulfill parts of the obligations and due to the complexity of the topic, many suppliers are struggling to support such requirements and often try to avoid them. However, VINCORION sees offsets as a further step to partner with its customers and support them not only with quality products, but also second them with the whole challenge, as industrial participation is often considered.

“Understanding the requirements of each specific case to its full extent is the centerpiece,” says Jenny Tsakalou, Senior Offset Manager at VINCORION. “If, and only if, we start working closely with the local industry and explore potential synergies, because unless you know you truly understand your partner’s capabilities, concerns, and long-term goals, you cannot go into depth with your business relationship. These synergies could not only be related to the main program under consideration but might also have to do with our wider product portfolio or technology roadmap,” adds the aeronautical engineer Tsakalou.

In doing so VINCORION seeks primarily for long-term relationships. The company works with existing subcontractors, but also wishes to identify suitable new in-country partners that it can do go the extra mile with, increase competitiveness with cost reductions, improved lead times, co-develop new products, and pursue further opportunities together in the country and globally. Furthermore, the company’s quality department is experienced with qualifying new suppliers and the engineering department is prepared to provide the required technical assistance, support, and troubleshooting.

VINCORION has already set high standards with its offset management in the past and is seeking more. Its aim is no less than to utilize industrial participation as a strategic key enabler for international growth. “We want to become a reference organization within the environment of international industrial participation by structuring, negotiating, and implementing offset projects with our primary objective to facilitate and support our own and our customers’ long-term global growth strategy,” comments Jenny Tsakalou.

Valuable Industrial Participation Performance Established

One good example VINCORION established was in Eastern Europe, specifically in Poland. Some years ago, the country decided to upgrade its tanks and had several localization requirements. Therefore, VINCORION worked closely with the local industry, explored its technical competencies, and successfully qualified local partners for component production, as well as acquiring lifetime maintenance and repair capabilities of the system.

As similar professionals know, the risks associated with localization are high, since it is directly related to the main contract. A delay in the localization project may cause a delay in the main program and therefore in the overall program performance. Hence, spending a lot of time was essential for VINCORION to identify the best local partners and establish a relationship that meant all parties were satisfied.

VINCORION GmbH

Feldstraße 155

22880 Wedel, Germany

www.vincorion.com