Ever since humans first realized the advantages of some form of protection against weapons, in the form of armour, there has been a continuous effort to find and maintain the optimum balance between protection and weight, as both threats and materials have evolved. If too little armour is added, protection is insufficient. If too much armour is added, mobility and payload suffers. As such, much work has historically gone into exploring new materials for use in armour protection, to identify those that provide greater protection at lower weight.

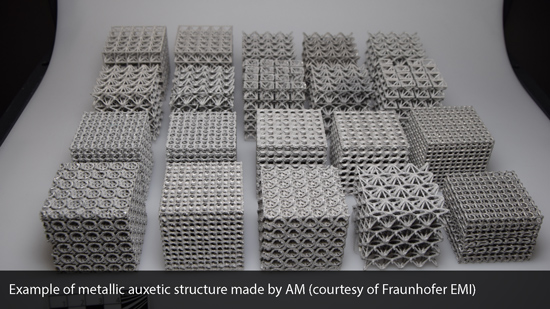

In order to explore the potential of novel materials and manufacturing technologies in this context, the European Defence Agency (EDA) on 21 October 2020 issued a press release announcing the launch of their “AMALIA” project. AMALIA is the acronym for “Additive Manufacturing of Metallic Auxetic Structures and Materials for Lightweight Armour”, and the project will explore the use of additive manufacturing, also known as 3D printing, to create metallic so-called “auxetic” materials for armour applications.

Auxetic materials are characterized by a negative Poisson’s ratio, meaning that the material or structure grows thicker when stretched, and thinner when compressed, due to its micro or macro structure.

As it applies to armour, simulations indicate potentially significant advantages to auxetic materials. In case of a violent impact, such as from a projectile or a fragment, the auxetic armour grows denser around the zone of impact – as the incoming threat impacts and compresses the armour, the auxetic characteristics of the material causes it to “contract” around the impact, increasing the density locally. A denser material absorbs more energy, leading to increased ballistic protection and, since the increased density occurs only at the actual point of impact, auxetic armour has the potential to provide a given level of ballistic protection at a lower weight than conventional armour.

Despite the significant potential advantages of these materials, the work that has been done up until now has remained mostly theoretical. This is due to the fact that auxetic materials and structures are highly challenging to create and produce using traditional manufacturing methods.

To try and push beyond this limitation, the AMALIA project is intended to explore the use of additive manufacturing, as well as novel metal alloys developed specifically for additive manufacturing, to create metallic auxetic materials for armour applications.

The project will make use of detailed simulations of auxetic materials and structures to evaluate their responses to impact loading, such as from a projectile, and to identify and optimize the parameters for future creation and production of these simulated structures, hopefully leading to lighter and better armour.

The current budget for the AMALIA project is just under 5 mill. Euro, and it is funded by EDA member states Italy, Czech Republic, France, Germany, Poland, Romania and Slovenia. The project will be led by the Italian company RINA Consulting – Centro Sviluppo Materiali Spa, located south of Rome. RINA Consulting specializes in the design of materials, and the optimization and development of manufacturing processes, which gives them the background and experience needed to act as lead on the project.

In addition to armour protection, auxetic materials also have potential applications everywhere where light, robust shock-absorbing materials are required.

EDA: EDA was established on 12 July 2004, “to support the Member States and the Council in their effort to improve European defence capabilities in the field of crisis management and to sustain the European Security and Defence Policy as it stands now and develops in the future”. EDA currently has 26 member nations, and plays a central role in supporting European Union defence initiatives, defence capability development as well as research and technology. EDA also conducts procurements on behalf of the member nations, and provides support to EU defence industry.

Thomas Nielsen