Self-propelled mortar and ammunition overview

Sidney E. Dean

Self-propelled (SP) mortars remain crucial in providing support to fast-paced operations by mounted, mechanised and armoured forces. In addition to tracked and 8×8 wheeled armoured vehicles, mobile mortars are increasingly being mounted on 4×4 vehicles.

While mortars come in various calibres, vehicle-mounted mortars usually range from 81 mm (medium) to 120 mm (heavy), although a few larger calibres are in service. Given the high trajectory of mortar fire, it can be especially effective against defilade targets as well as against the comparatively weaker top surface of armoured vehicles. Various improvements and new technologies are now incorporated into mortar systems to enhance lethality and make them easier to use. These include onboard fire control systems (FCS) and integration into situational awareness networks to enhance target acquisition and increase engagement speed. Laser rangefinders, day/night optical sights and automatic gun laying systems make targeting more precise and permit faster target engagement.

Credit: Italian Army

Some now feature multiple round simultaneous impact (MRSI) capability through automated adjustment of firing trajectories, ensuring several mortar bombs can strike the target area at the same time. This can improve fire mission effectiveness, particularly against an unprepared opponent, but can only be performed within a certain range.

Mortar ammunition developments

According to a forecast by Mordor Intelligence, the global mortar ammunition market is expected to grow from an estimated USD 87.46 billion in 2024 to USD 111.84 billion in 2029, reflecting a compounded annual growth rate (CAGR) of over 5%. This growth is partially due to efforts to increase stocks in times of crisis, and to some extent, due to efforts to develop and procure advanced munition types. Desired enhancements include lighter weight, increased lethality, extended range and precision-guidance capability. Several leading firms have been introducing significantly upgraded ordnance.

General Dynamics Ordnance and Tactical Systems (GD-OTS) introduced the 81 mm Roll Controlled Guided Mortar (RCGM) in 2012. Target coordinates are programmed into the munition via a portable global positioning system (GPS) setter. Once fired, the round’s onboard global navigation satellite system (GNSS) guidance system constantly fine-tunes the aft-mounted steering canards to keep it on target. GD-OTS cites a circular error probable (CEP) of 5 m, enabling two RCGM bombs to precisely destroy a target which the manufacturer claims would typically require 10–18 unguided mortar bombs to achieve the same effect. In 2013, the firm also fielded the 81 mm mortar anti-personnel anti-materiel (MAPAM), claimed to possess twice the lethality of conventional mortar rounds of the same calibre. The primary lethality radius extends to 55 m, with a further danger zone extending to 130 m from impact. According to GD-OTS, the pre-fragmented payload can be tailored to the user’s requirements to optimise lethality against various target sets, while providing precision control over the danger zone. Minimum and maximum range are 130 m and 5.5 km respectively, while muzzle velocity can be scaled from 80 m/s to 292 m/s.

Credit: GD-OTS

Elbit Systems’ Stylet 120 mm guided mortar bomb can strike targets at a range of 1–8.5 km and is outfitted with a multimode GNSS/INS guidance system which provides a CEP of less than 10 m. The automated fire control system requires no ranging to assure first-round hits on target, and can allow multiple targets to be engaged without having to change the mortar’s angle of fire. According to Elbit, the high explosive fragmentation (HE-FRAG) warhead is effective against infantry and light armoured vehicles. Elbit also off the extended range Rapier 120 mm GNSS/INS guided bomb, which is capable of striking targets out to 16 km, and according to the manufacturer it remains accurate even in severe weather conditions.

In 2021, Elbit Systems introduced the Iron Sting munition, with a range of 1–12 km. This 120 mm guided mortar bomb has both semi-active laser (SAL) guidance, as well as INS/GNSS guidance. The former guidance mode allows a CEP of about 1 m, while the latter permits a CEP of around 10 m. According to Elbit, the Iron Sting’s HE-FRAG warhead is capable of penetrating 20 cm of double reinforced concrete, making it suitable against fortified positions. All three of the aforementioned Elbit mortar bombs have a multi-mode fuze which offers a choice of proximity detonation, point detonation or point detonation delay. Additionally, the manufacturer states for all three, that the mission loading time (from target data input to projectile launch) is 15 seconds, with no meteorological data input required.

It should be noted that while SAL guidance for mortars isn’t new – for instance, the KBP ‘Kitolov-2’ 120 mm SAL-guided mortar bomb was accepted into Russian service on 31 December 2002 – widespread adoption and proliferation of this technology has been somewhat slow. SAL guidance has particular utility in urban combat, as it allows mortar bombs to be guided into narrow alleyways, through windows, or onto a specific vehicle. This also allows a user to significantly reduce collateral damage compared to an unguided mortar fire mission. The SAL seeker requires the target to be illuminated by an external ground-based or airborne laser source; the seeker detects the aim point of the laser and homes in on it.

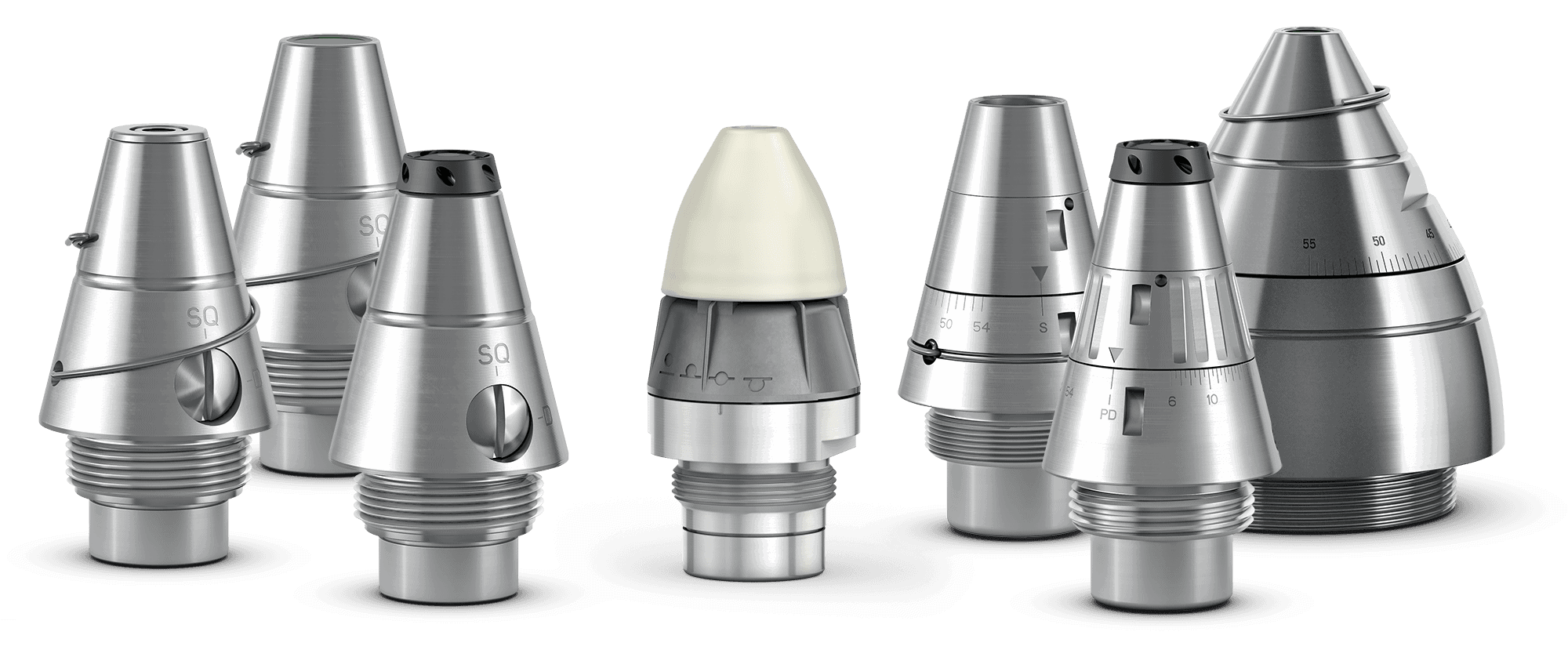

Beyond seekers, fuze technology is generally progressing. Junghans Defence has introduced the Furya dual-mode fuze which can be set for either proximity or impact fuzing modes. Furya is suitable for various artillery munitions including 120 mm mortar bombs. Selection of the fuzing mode can be made inductively or manually, without a fuze setter. According to the manufacturer, the sensor is highly resistant to electromagnetic interference. Junghans has also introduced the electronic multi-option Flame fuze for high explosive (HE) mortar rounds. Operators can choose between four detonation modes: two proximity modes with different detonation heights, and two impact modes with or without detonation delay. The fuze is suitable for all NATO standard mortar calibres.

Credit: Junghans Defence

US Army mortar choices

The United States Army currently operates the M1064A3 self-propelled mortar mounted on the tracked M113 armoured personnel carrier, and the M1129/M1252 mortar carrier variant of the wheeled Stryker. The M1064A3 is equipped with the M121 120 mm carrier mounted mortar system produced by Elbit Systems, and carries 69 rounds along with their charges on board. Situated on a turntable in the rear of the M113, the mortar has a 90° range of traverse (45° left/right of centre). The integrated M95/M96 Mortar FCS – Mounted (MFCS-M) interfaces with the M577A3 mobile command post/fire direction centre vehicle; the networked, digital fire control system allows the mortar to receive fire missions on the move, stop, fire, and reposition within one minute. The Army has now begun the multi-year transition from the M113 to the armoured multi-purpose vehicle (AMPV); this will include the ultimate replacement of the M1064A3 by the M1287 AMPV mortar carrier variant.

The Stryker M1129/M1252 mortar carriers utilise the turntable-mounted Recoil Mortar System 6 – Light (RMS6L) 120 mm, based on the Cardom 10 mortar system developed by Israeli company Soltam Systems, a subsidiary of Elbit Systems. The Stryker’s mortar system also integrates the M95/M96 FCS. The weapon system has a maximum rate of fire of 16 rounds per minute (rpm) and a sustained rate of 4 rpm, with a maximum range of around 8 km.

Both current US mortar carriers require the mortar hatch to remain open while firing, placing the crew at greater risk from counterfire. The US Army has been seeking to replace the muzzle loading weapons with breech-loading, turret mounted mortars which would allow the crew to remain under armour protection. To this end, in 2020, the Pentagon entered into a Cooperative Research and Development Agreement (CRADA) with Finland’s Patria Land Oy to determine whether the Patria’s NEw MOrtar (NEMO) system could be adapted to US platforms. The turreted, remote-controlled system is specifically designed for light tracked or 6×6/8×8 wheeled vehicles, and in the land role it has been installed on the Slovenian Army’s Patria AMV 8×8 and the Saudi Arabian National Guard’s LAV II 8×8. NEMO is compatible with all standard 120 mm smoothbore mortar bombs, including guided variants. The NEMO’s semi-automatic loading system allows a maximum burst rate of fire of 10 rds/min, with sustained fire of 7 rds/min. The system is capable of delivering a 6-round MRSI, and also possesses a fire-on-the-move capability.

Credit: US Army/Patrick A. Albright

While the Pentagon has not announced any decisions regarding a mortar turret for the Stryker, the M1287 will be armed with a Patria NEMO supplied by Patria and Kongsberg Defence and Aerospace. As reported by Janes in December 2023, the AMPV mortar carrier will be publicly introduced at the Army-hosted annual Maneuver Warfighter Conference at Fort Benning, Georgia in September 2024. Janes also reported that BAE Systems’ AMPV director Bill Sheehy stated that the event would include a live-fire demonstration of the prototype system.

European mortar systems

HSW M120 Rak

Turreted systems are becoming increasingly popular due to the enhanced crew protection and often automated fire control. Poland’s M120 Rak SP mortar system has been operational since 2017, with the latest tranche delivered in September 2023. The M120 turret, armed with a 120 mm breech-loaded mortar, is produced by Huta Stalova Wola (HSW), and mounted on a Rosomak 8×8.

The vehicle carries 20 ready-to-fire mortar bombs in a turret magazine, plus an additional 26 rounds stored in the hull. Using extended range munitions, the mortar can strike targets at 15 km. The mortar can also fire within 30 seconds of reaching a firing position, and relocate within 15 seconds of firing. The WB Group TOPAZ FCS used by Rak is capable of automatic gun laying onto the coordinated selected on the accompanying digital map display, and for direct fire mode, the turret is equipped with a BAZALT sight with day and thermal channels, as well as a laser rangefinder. The M120 turret has also been offered on the M120G Rak variant, which is based on the Opal light tracked platform – a Polish domestically-developed variant of the MT-LBu design.

Thales 2R2M MEPAC Rifled Mortar

However, open-hatch systems continue to be fielded including the Mortier Embarqué Pour l’Appui au Contact (MEPAC) system which will mount the Thales 120 mm rifled, recoiled mounted mortar (R2M2) system on the French Army’s VBMR Griffon 6×6 armoured vehicle. Although the configuration used requires the roof hatch to remain open for firing, crew members need not expose themselves above the roofline, as the mortar is breech-loaded through a tray located at the base of the barrel. The weapon is mounted on a turntable which allows the weapon to traverse through 360°, enabling the system to fire in any direction. Unlike many mortars in this category, the R2M2 is rifled, enhancing accuracy and range. Using SAL guided munitions, the MEPAC will be able to strike targets at a range of 17 km.

MEPAC is due to begin fielding with the French Army in 2024. The Belgian Armed Forces have also opted to acquire this system. The 2R2M is currently in service on several other tracked and wheeled vehicles in Italy (mounted on the Freccia platform), Malaysia, Oman, and Saudi Arabia.

Patria/BAE AMOS/Mjölnir

Multiple-barrelled mortars remain quite rare. A notable exception is the Advanced MOrtar System (AMOS) jointly developed by Patria and Hägglunds AB (now BAE Systems Hägglunds). the 120 mm smoothbore turret-based mortar uses semi-automatic breech-loading mechanism to allow rapid reloading. The system entered service in 2013 with the Finnish Army on the Patria AMV 8×8 platform, and bearing the XA-361 service designation. Finland remains the sole operator of this system. The double-barrelled configuration enabled AMOS to attain a maximum rate of fire of 16 rds/min, and capable of a 10-round MRSI fire mission. The system is also capable of credibly engaging armoured targets, for instance, through the use of infrared (IR) homing, high-explosive anti-tank (HEAT) Strix rounds developed by Saab Bofors Dynamics.

Credit: BAE Systems

Compared to AMOS, BAE Systems’ Mjölner mortar system is a simpler implementation of the twin-barrel mortar design, relying on a manual muzzle loading system via two loading tubes running parallel to the two barrels. Unlike AMOS’ 360° of traverse, Mjolner has a more limited traverse range of 60° (30° left or right of centre). However, owing to its lower-complexity loading system, Mjolner has an inherently lower chance of experiencing failures through breakages of electronic or mechanical subcomponents, and is estimated to be somewhat cheaper and simpler to maintain than AMOS. The manufacturer has stated that the weapon is capable of attaining a maximum rate of fire of 16 rds/min, with the first four rounds fired in under eight seconds.

Sweden has ordered a total of 80 Mjolner systems mounted on the CV90 tracked platform. The first units were delivered in 2019, with the complete order due to be fulfilled by 2025. The CV90 Mjolner system requires two personnel to load the weapon, plus a commander and driver. It is compatible with all NATO standard 120 mm mortar ammunition, including Strix. Up to 56 projectiles are carried in the turret bustle, with another 48 rounds stored in the hull.

Israeli and Turkish options

Elbit Spear Mk2

In 2012, Elbit subsidiary Soltam Systems introduced the Spear 120 mm mortar system, as a derivative of the Cardom mortar. It was optimised for use on light vehicle platforms through the use of a soft recoil system, which reduces the recoil load to 11-13 tonnes, down from around 30 tonnes for typical 120 mm systems firing at full charge.

The upgraded Spear Mk2 variant introduced in 2017 provides greater automation of fire control, including automatic gun laying. It can be operated by a two-person crew in manual or fully autonomous mode. Via a battle management system (BMS), the Spear Mk2’s FCS can directly interface with offboard sensors, including UAVs for enhanced targeting. Elbit states that the mortar carrier can be into and out of action within 60 seconds, and can attain a maximum rate of fire of 16 rds/min, or a sustained rate of 4 rds/min.

Elbit Sling

Elbit’s Sling 120 mm SP mortar system is toward the special operations market end of the market. The mortar is integrated with an electronically-operated rig and provided with a baseplate, requiring it to be lowered to the ground for firing. This arrangement allows it to be mounted onto fairly light 4×4 platforms, since the recoil forces are absorbed by the ground rather than the vehicle suspension. However, this also means that it is not necessary to use a low-recoil mortar design. The Sling completed development and testing in 2023.

Credit: Elbit

For transport, the mortar and baseplate are folded forward onto the rear of the vehicle, which renders the vehicle sufficiently low to be air-transportable by a suitably-sized helicopter. The weapon is manually loaded, but gun laying is automatic, with manual backup, with a weapon traverse arc of 220° (110° left/right of centre). Similarly to Spear, the manufacturer states that Sling has an into and out of action time of 60 seconds, and can attain a maximum rate of fire of 16 rds/min, with a sustained rate of 3-4 rds/min. Sling is in use by the IDF, and has been tested by US Special Operations Command (SOCOM) received a unit for testing in May 2022.

Elbit Crossbow

Elbit’s Crossbow turret-based 120 mm mortar intended for 6×6 and 8×8 platforms is under development and expected to be fielded with the IDF in 2025. It is capable of firing out to 10 km at maximum charge, is capable of firing on the move, and possesses a six-round MRSI capability. A relatively unique attribute is the autoloader design which aligns fresh rounds with the current position of the barrel, allowing the barrel to remain trained on target rather than needing to be returned to the loading position after firing each round.

Aselsan Alkar 120/81 mm

The majority of mortars described in this article have been 120 mm systems, which have greater range and effect than smaller mortars. However, 81 mm SP systems remain in demand due to their flexibility and portability. Aselsan’s Alkar mortar range includes both 120 mm and 81 mm models. The 120 mm variant is in service with the Turkish Gendarmes, mounted on a BMC Vuran 4×4 protected patrol vehicle (PPV). The 81 mm variant has dimensions of only 1.85 × 0.85 × 1.02 m (LWH) and is suitable for fairly light armoured or soft-skinned vehicles such as pickup trucks. The modular system can accept any standard 81 mm barrel, whether rifled or smoothbore, depending on user requirement. The effective range is between 100 m and 6.4 km depending on barrel and munition. The weapon is equipped with an automatic gun laying system with manual backup, and the FCS can directly receive targeting data from forward observers and radar. The electromechanical turntable allows the barrel to traverse 180° (90° left/right of centre).

Credit: Aselsan

Closing thoughts

The renewed emphasis on large-scale manoeuvre warfare and great power conflict has raised the value of self-propelled mortars as tactical support for mounted, mechanised and armoured forces. Given the sophistication of modern air defences and electronic warfare capabilities, ground forces in peer conflicts may have to rely less on air support and more on organic artillery. Within the tactical artillery category, mortars present some attributes which differentiate them from howitzers and rocket artillery. They have considerably shorter range, and are therefore generally operated closer to the line of engagement and controlled at a lower tactical echelon. This increases their flexibility and the ability to quickly redirect fire as the battle unfolds or as a unit’s tactical UAVs detect targets of opportunity. This makes them especially valuable for forces relying on fast and decisive artillery support or quick strike capability against targets of opportunity. These attributes will keep mortars in high demand for a long time to come.

Sidney E. Dean